CakeFormingWinder

Winding machine

With the CakeFormingWinder - a glass yarn filament winding machine that is new in many respects - Saurer exactly satisfies the desires and requirements of its customers, and in doing so relies on innovative technologies.

Thus the CakeFormingWinder with for instance the aid of the new rotor technology and by integration of a high-speed traversing system is able to achieve efficient production of high-quality glass filament packages.

In addition to the CakeFormingWinder, Saurer offers an attractive portfolio of services to suit the requirements of customers engaged in glass fibre production. We offer a wide range of individual service solutions to ensure trouble-free and profitable operation, from project planning to the service warranty and reliable supply of original parts.

With the CakeFormingWinder - a glass yarn filament winding machine that is new in many respects - Saurer exactly satisfies the desires and requirements of its customers, and in doing so relies on innovative technologies.

Thus the CakeFormingWinder with for instance the aid of the new rotor technology and by integration of a high-speed traversing system is able to achieve efficient production of high-quality glass filament packages.

In addition to the CakeFormingWinder, Saurer offers an attractive portfolio of services to suit the requirements of customers engaged in glass fibre production. We offer a wide range of individual service solutions to ensure trouble-free and profitable operation, from project planning to the service warranty and reliable supply of original parts.

Features and benefits

- High yarn quality thanks to constant winding speed

- High-speed traversing of the collet

- Water-cooled control unit

- Automatic lubrication system

- Angular timing of the rotor

and more...

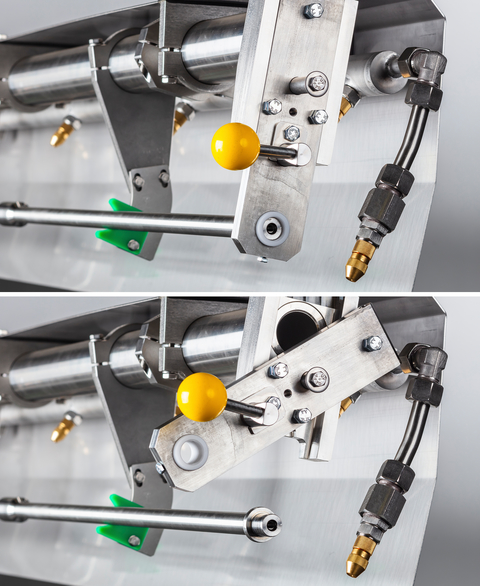

Quick-Exchange Flyer

The innovative concept of the Quick-exchange flyer permits extremely quick and straighforward exchange of the complete flyer unit.

Advantages:

- Quick exchange of the shaft uni

- Short standstill time

- Maintenance-friendly design

- Sprayed water protection of the shaft bearings

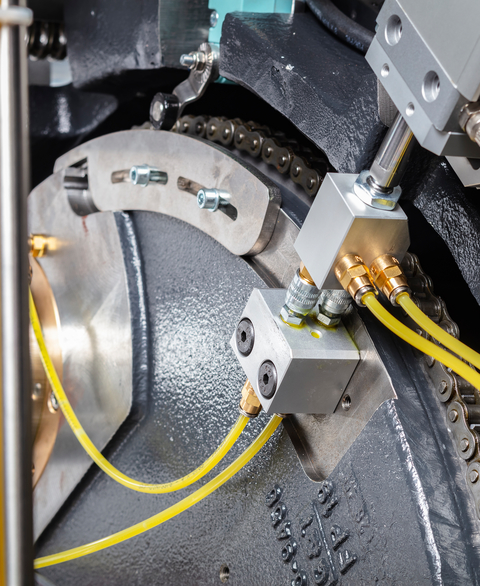

Automatic lubrication system

The CakeFormingWinder is equipped with an automatic lubrication system specially developed to satisfy these requirements. This is programmable and adjusts automatically to the respective docking situation. This ensures the correct supply of lubricant, which enables continuous 24-hour operation without interruptions. Lubrication intervals and lubrication quantities are flexibly configured, using the latest control technology.

Advantages:

- Automatic supply of lubricant: Rotor, rotor traversing drive und recirculating ball drives

- Low maintenance requirements

- Long working life

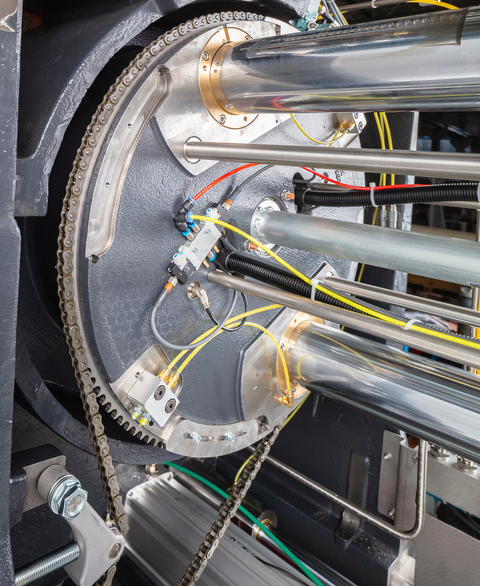

Angular timing of the rotor

This technology permits selection of the optimum position of the rotor in relation to the glass filaments emerging from the nozzle. The growth of the package diameter is thus continuously tracked by the rotor. By this means the yarn path in the flyer shaft geometry is optimised during the winding process.

Advantages:

- Optimum strand running angle

- High yarn quality

- Continuous adaptation to the package diameter

Operating unit

The Winder Operator Box (WOB) interface allows control of all CakeFormingWinder processes relevant to production.

The spatial arrangement on the textile side ensures short distances and supports the operator during operation.

The WOB incorporated within the central control system displays amongst the current operation status and permits precise and direct influence on the process parameters.

Advantages:

- Pivoting control cabinet

- Automatic lubrication unit

- Easy accessibility to maintenance assemblies

- Display of pending exchange

Picture gallery

Related articles

Here you will find further information – for example application reports, customer success stories and interviews – about the above product.

Downloads

Find out more about our products. Here we provide you with all the relevant documents for download in PDF format.