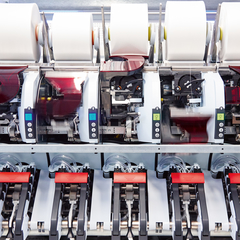

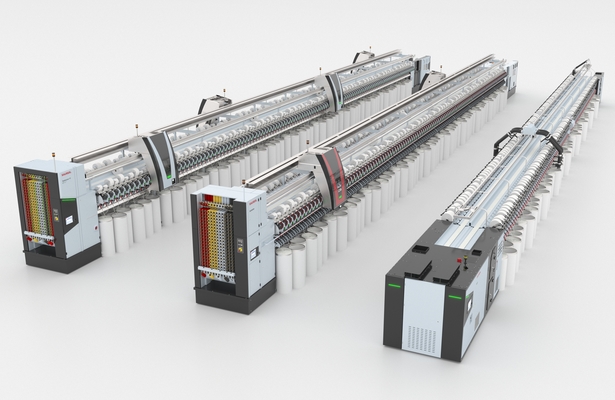

Automatic rotor spinning machine

Autocoro 10

Think ahead

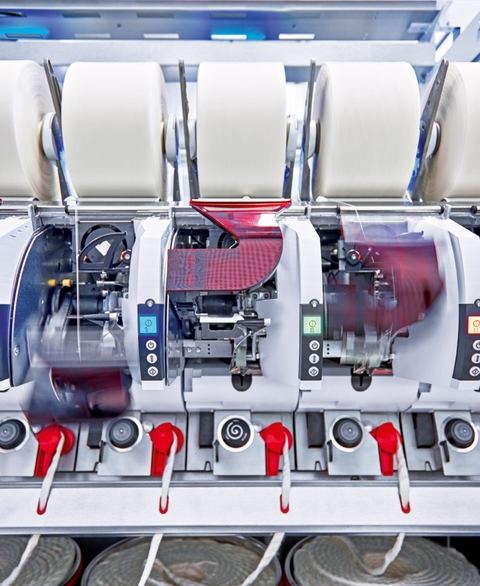

Saurer launches the 3rd generation of revolutionary Autocoro 10 individual-drive technology. Unprecedented productivity due to intelligent automation and digitalization. The secure platform for Industry 4.0 in the rotor spinning mill.

Saurer launches the 3rd generation of revolutionary Autocoro 10 individual-drive technology. Unprecedented productivity due to intelligent automation and digitalization. The secure platform for Industry 4.0 in the rotor spinning mill.

E³: Our development philosophy

The needs of our customers are our top priority. With every new or further development, we pay attention to reducing energy consumption, increasing efficiency and improving ergonomics. The E³ philosophy underlies all our designs and our smart solutions provide added value to customers. With the transformation of the textile industry for the Circular Economy, the processing of sustainable fibres is another important focus point in our developments.

- Minimum energy costs

- Maximum cost transparency through energy monitoring

- Synchropiecing 36

- Up to 8 doffers DCU

- Vacuum trash cleaner VTC

- Digipiecing und Digiwinding

- Multilot 2, 3 und 5

- Pilotspin

- Seamless lot change

- Digital yarn quality assurance with Corolab XQ and Corolab XF

- Colored symbol display for visualization and separation of different lots

Highlights

- 50 % higher piecing capacity with Synchropiecing 36

- Run-up in less than 10 minutes

- Up to 5 % more productivity due to increased doffing capacity up to 8 DCU

- Higher waste tolerance with the new, flexible spin box and vacuum trash cleaner VTC

- Senses for analysing all spinning data in one program – in real time, safely and from anywhere

Picture gallery

Impressions of Autocoro 10

Schlafhorst Systems rotor spinning

Schlafhorst Systems offer the highest versatility in the market. Whether an application requires the uniqueness and productivity of air spinning or the smart flexibility of rotor spinning, we have the right solution for you.

Downloads

Find out more about our products. Here we provide you with all the relevant documents for download in PDF format.

Brochure_Autocoro10_EN

1.81 MB

Brochure_Autocoro10_TR

1.81 MB

Senses

With a single program, you can now manage your Saurer machines. Senses bundles and analyzes production, quality and performance data. Secure and from everywhere.

Strong and reliable life-cycle partnership.

Unique smart solutions to increase the benefit to the customer.

Notable performance and sustainability throughout the machine lifetime.

We keep you competitive.