Bearings for rotor spinning

Unique development from a single source.

Rotor Bearing RB 120 - setting new standards in rotor spinning

Precision meets innovation - elevate your yarn production.

Introducing a fundamentally new, patented bearing design with integrated resilient mounting – developed specifically for direct-driven open-end spinning machines. This innovative solution combines resilience, durability, and precision to unlock the full performance potential of your OE spinning machines.

- Rotor bearing for operational speeds between 90.000 and 120. 000 rpm

- Achieved by combining the resilient mounting and the bearing in a completely new patented design

- About 10 % - 15% speed and productivity increase

- Compatibility with excisting direct driven open-end machines at their full capacity

- For a wide range of fibres like cotton, blends and recycled fibres

- Machine compatibility: SAURER, RIFA, TAITAN, RIETER

Easy handling

- Resilient mounting is inherent part of the bearing

- Relubrication in the machine

- Quick opening and closing of the relubrication holes without tools

Video

The Performer RB 105

With the RB 105 system, Texparts offers the complete rotor system for high-performance spinning. The joint performance of Texparts RB 105 rotor bearing, resilient mounting and rotor cup creates a symbiotic set for reduced installation cost and highest spinning speeds up to 105 000 rpm.

The field of application covers a wide range of fibers such as cotton, cotton blends and recycled fibers.

Video

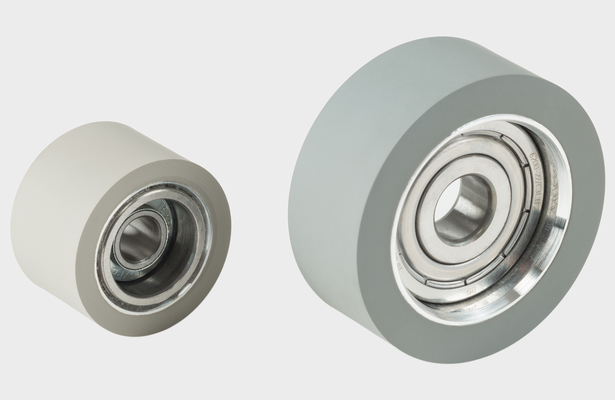

Delivery rollers CK 12

Texparts delivery rollers CK 12 ensure constant yarn processing and are available with or without cots.

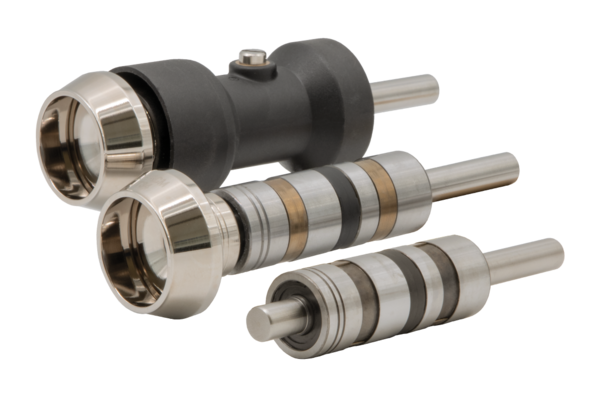

Rotor bearing TL

Texparts TL Rotor bearings for direct driven open end machines are integrated bearing units with highest requirements concerning the accuracy of manufacturing. The honed raceways of the bearing are fitted directly into the shaft and the bearing housing. The choice of a premium rotor bearing allows higher rotor speeds and an increase in production of manual or semiautomatic rotor spinning machines.

The TL Bearing units offer the right solution to upgrade a mid-tier to high-tier rotor spinning machine. The smooth running behaviour of the rotor bearing has an essential influence on the yarn evenness.

| Rotor bearing | TL 2260 | TL 2280 | TL 2290 |

|---|---|---|---|

| Max. speed (rpm) | 60 000 | 80 000 | 95 000 |

Advantages

Bearing geometry designed for very high rotational speed and highest productivity

Long maintenance intervals due to highest manufacturing precision

Use of high-tech materials with best tribological characteristics for minimizing friction and wear

Optimized bearing design and efficient sealing system

Rotor bearings TL

Texparts TL rotor bearings for direct driven open end machines are integrated bearing units with highest requirements concerning the accuracy of manufacturing. The honed raceways of the bearing are fitted directly into the shaft and the bearing housing. The choice of a premium rotor bearing allows higher rotor speeds and an increase in production of manual or semiautomatic rotor spinning machines.

The TL bearing units offer the right solution to upgrade a mid-tier to high-tier rotor spinning machine. The smooth running behaviour of the rotor bearing has an essential influence on the yarn evenness.

| Rotor bearing | TL 2260 | TL 2280 | TL 2290 |

|---|---|---|---|

| Max. speed (rpm) | 60 000 | 80 000 | 95 000 |

Advantages

- Bearing geometry designed for very high rotational speed and highest productivity

- Long maintenance intervals due to highest manufacturing precision

- Use of high-tech materials with best tribological characteristics for minimizing friction and wear

- Optimized bearing design and efficient sealing system

Opening rollers LE

Texparts opening rollers LE set the standard for the yarn quality as well as productivity. The internal forces at an average speed of 9500 rpm during the combing process have a high impact on the bearings and therefore only premium bearings will fulfill these demands. Two types of beater bearings LE 222 and LE 1630 are available - each with and without adaptor ring.

Bearing units IL

Texparts bearing units IL are designed for twin-disc drives in mainly fully automatic premium rotor spinning machines and are available in two types: IL 13 and IL 14.

Downloads

Find out more about our products. Here we provide you with all the relevant documents for download in PDF format.