Senses Recipe

Advanced settings.

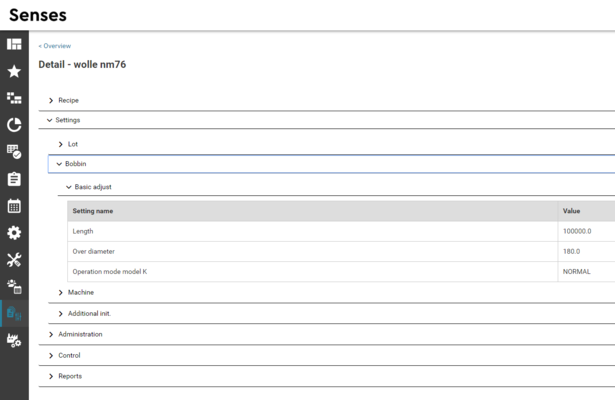

With Senses Recipe, you can digitalize your recipe management. It enables you to monitor and adjust the settings of your machines.

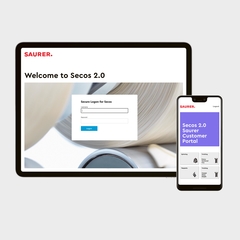

Using the Senses Element Recipe, you can load all production settings and recipes of the machine into Senses. Additionally it is possible to compare, modify and assign recipes to specific machines.

With Senses Recipe, you can digitalize your recipe management. It enables you to monitor and adjust the settings of your machines.

Using the Senses Element Recipe, you can load all production settings and recipes of the machine into Senses. Additionally it is possible to compare, modify and assign recipes to specific machines.

Features and benefits

- Efficient management of recipes

You can select and change recipes, track variances in recipe values, keep recipes secure, track recipe changes and analyze recipes - Fast and secure recipe assignment

You can digitally send recipes to specific machines and avoid operational mistakes - Export of all machine settings in Senses

The centralized storage and the setting overview of all machines brings transparency - Best setting for the machine

The central setting overview secures that the right setting is on the right machine - Reduced machine set-up times

Automatic saving of setting changes on the machine as snapshot and the highlighting of differences in settings between machine / group decrease the set-up times - Higher product quality

Reduce the off-quality by insuring the correct setting on the machine - Valuable database

Data collection for future Senses analysis functions to optimise your machine settings - Intuitive Senses user interface

Short induction time due to simple and clear design

Content of Senses Recipe

- The user can view, save and download all of the machine's recipes in Senses

- It is possible to compare the settings of different machines or groups

- Senses recognizes when a setting has been changed on the machine

- All changes are registered with the time / date and are available in the future

- Can be used on mobile devices

- Senses Recipe can be purchased and the licenses activated in the Senses software shop (integrated in Senses)

Areas of application

- Available for online machines (special software version must be installed)

- Roving: Starting from machine generation 670

- Ringspinning: Starting from machine generation 351

- Rotorspinning: Starting from machine generation ACO 8

- Airspinning: Starting from machine generation Autoairo

Picture gallery

Impressions of the Senses Element Recipe.

Downloads

Find out more about our products. Here we provide you with all the relevant documents for download in PDF format.

Fact Sheet Senses Recipe EN

1.80 MB

Senses

With a single program, you can now manage your entire production and quality assurance facilities along the textile chain. Senses, the digital Mill Management System from Saurer, bundles and analyzes production, quality and performance data across all divisions. Even machines from third-party manufacturers can be managed. In real time. Secure. From everywhere.

Strong and reliable life-cycle partnership.

Unique smart solutions to increase the benefit to the customer.

Notable performance and sustainability throughout the machine lifetime.

We keep you competitive.

Digital Team

Should you have questions about Senses, Senses Elements, the Calculator App or require additional guidance, kindly get in touch with our Digital team. As your partner, we pride ourselves in providing expert and swift support. You can reach us at info.senses@saurer.com.