GlassTwister

Ring twisting machine

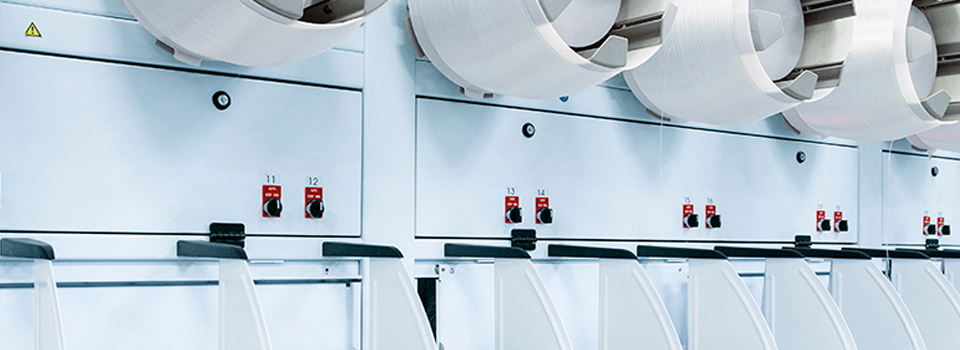

Our GlassTwister is an innovative high performance ring twisting machine for winding up glass filament and plied yarns and has become well established in the market. Our twisting systems provide an optimum level of variability and flexibility.

Along with a range of services oriented toward customer needs, there is an attractive comprehensive package available - from project planning to the service warranty and original part availability spanning all machine generations.

Our GlassTwister is an innovative high performance ring twisting machine for winding up glass filament and plied yarns and has become well established in the market. Our twisting systems provide an optimum level of variability and flexibility.

Along with a range of services oriented toward customer needs, there is an attractive comprehensive package available - from project planning to the service warranty and original part availability spanning all machine generations.

- Lower energy consumption due to optimized drive motors and bearing technology

- Optimized smooth running of the ring rail system due to drive systems without counterweights

- Higher economy in the fine yarn sector and the best finished package quality

- 100% tested sectional design, leads to faster production start

- Really low process-related yarn break rates

- Improved ergonomics and user-friendly machine due to low-height design

- ≤ 82 dbA noise emission

- Individual adaptations to your requirements

Advantages for the customers:

- high productivity and flexibility

- production of all kinds of shape of packages

- excellent quality of take-up packages

- high economic efficiency and reliability

- low energy consumption

- low noise level

- an optimal ergonomic machine concept

- low maintenance costs

and more...

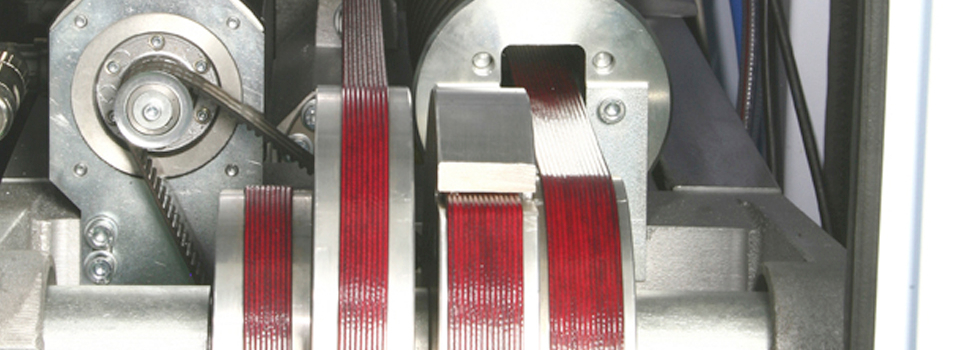

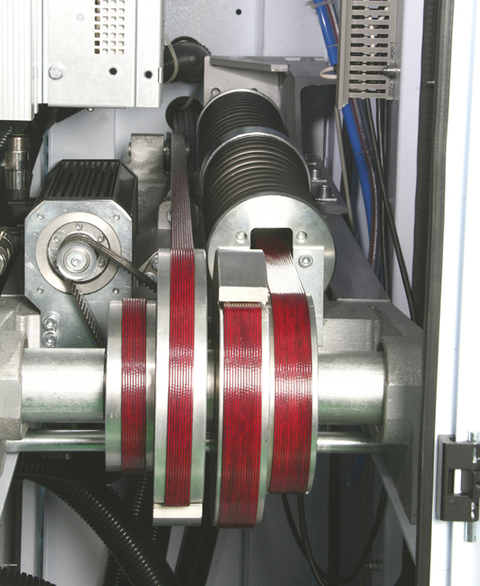

Single motor drive for spindles

The GlassTwister features single motor drive for spindles and baskets, which are centrally controlled via touch panel at the drive unit. The spindle can be adjusted individually.

You can rely on perfect yarn guidance by means of yarn balloon guide and balloon limiter ring. Thanks to the maintenance free bearings, the spindle units are extremely low-maintenance and sustainable.

Precise single synchronous motor drive

Operating is rendered more comfortable to the operating maintenance personnel thanks to the mature technical design, e.g. comfortable placement height. Every twisting position is equipt with an individually start and stop function.

Precise ring rail control

The ring rail control is monitored by linear encoder. Due to a central working spring compensation unit, use of counterweights is not necessary. Subsequent processes will run more smoothly with the optimum unwinding characteristics.

Picture gallery

Related articles

Here you will find further information - for example application reports, customer success stories and interviews - about the above product.

Downloads

Find out more about our products. Here we provide you with all the relevant documents for download in PDF format.

GlassTwister product brochure DE

1.88 MB

GlassTwister product brochure EN

1.87 MB

GlassTwister product brochure ZH

2.50 MB

GlassTwister product brochure RU

1.90 MB

CakeFormingWinder product brochure DE

1.74 MB

CakeFormingWinder product brochure EN

1.74 MB

CakeFormingWinder product brochure ZH

1.85 MB

CakeFormingWinder product brochure RU

1.75 MB

Strong and reliable life-cycle partnership.

Unique smart solutions to increase the benefit to the customer.

Notable performance and sustainability throughout the machine lifetime.

We keep you competitive.

Senses

With a single program, you can now manage your Saurer machines. Senses bundles and analyzes production, quality and performance data. Secure and from everywhere.