Zinser Systems

Ring spinning

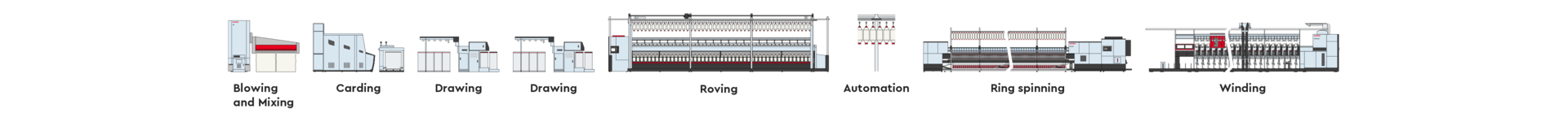

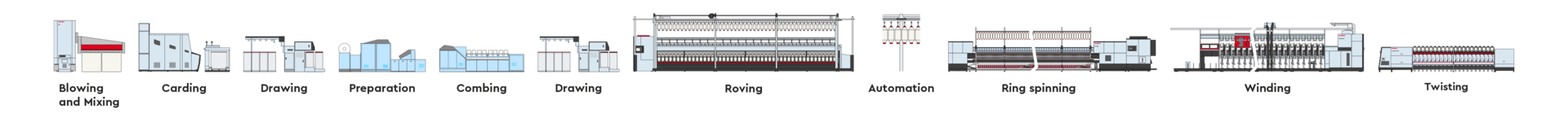

Zinser Systems offer a wide range of specialized ring spinning solutions from bale to yarn. Starting from the blow room and carding, Zinser Systems is designed to ensure the excellent processing of fibres. Efficient ring spinning machinery combined with intelligent winding machinery guarantee high yarn quality.

Zinser Systems offer a wide range of specialized ring spinning solutions from bale to yarn. Starting from the blow room and carding, Zinser Systems is designed to ensure the excellent processing of fibres. Efficient ring spinning machinery combined with intelligent winding machinery guarantee high yarn quality.

Process line for carded ring yarns

Process line for combed ring yarns

Your benefits

- Effective cost control, strong financial planning security, coordinated and fast installation, high level technical and technological services

- Market proven sliver and yarn quality

- Full quality and production data control and transparency

- Comfortable and common display for all machines

- Complete automation offers with competent engineering

- Great price-performance ratio of full package and attractive financing packages

- Alignment of the spinning mill according to your requirements

Ring spinning

From fibre disintegration through all five spinning processes to the twist package – Saurer is the only manufacturer in the world to offer a perfectly matched system for every textile application. It provides you with a turnkey solution from Saurer for every yarn, every quality and every market requirement. We invite you to take advantage of this comprehensive solution.

Modern ring spinning systems must not only enable first-class yarn quality, but also high productivity, flexibility and perfect automation. The Saurer ring-spinning machine ZR 72XL convinces by its modular design, because it adapts 100% to your needs. Ring yarns have a wide range of applications – from fine to coarse for almost all fibre types and blends. They can be used universally, for example in home textiles and outerwear.

Economic aspects and the final application of the yarns influence the specification of the individual process stages. With the Zinser Systems, Saurer offers you a process chain that is precisely tailored to your needs.

Typical textile applications with ring yarn

- Denim

- T-Shirts

- Awning

Jeans with carded cotton ring yarn

The most important features

- High tenacity

- Long life time

- Flexibility with Core-, Duocore yarn

- Fashion trends with fancy yarns

- High automation level due to Autoflow Systems

T-Shirts with combed cotton ring yarn

The most important features

- High tenacity

- Less pilling

- Good form stability

- Maximal wearing comfort with best maintenance properties

- Refined, glossy surface

- Special touch (smooth surface, softness next to the skin)

- Flexibility with Core-, Duocore and Fancy yarns

Awning with polyester ring yarn

The most important features

- High tenacity

- Long life time

- Good print quality

- High automation level due to Autoflow Systems

Your Saurer products for the production of carded ring yarns

|

Process |

Saurer products |

|

Data management |

|

|

Ring spinning |

|

|

Roving |

|

|

Drawing |

|

|

Drawing |

|

|

Carding |

|

|

Mixing |

|

|

Mixing |

|

|

Opening |

|

|

Opening |

|

|

Bale opening |

Your Saurer prioducts for the production of combed ring yarns

|

Process |

Saurer products |

|

Data management |

|

|

Ring spinning |

|

|

Roving |

|

|

Drawing |

|

|

Combing |

Cooperation partners |

|

Drawing |

|

|

Carding |

|

|

Mixing |

|

|

Mixing |

|

|

Opening |

|

|

Opening |

|

|

Bale opening |

Senses

With a single program, you can now manage your Saurer machines. Senses bundles and analyzes production, quality and performance data. Secure and from everywhere.

Strong and reliable life-cycle partnership.

Unique smart solutions to increase the benefit to the customer.

Notable performance and sustainability throughout the machine lifetime.

We keep you competitive.

Contact us