CarpetCabler

Direct cabling machine

Our CarpetCablers and CarpetTwisters have been successfully used for decades to produce high quality, premium yarns for quality carpets and other textiles in the most economical way.

They offer optimum possibilities for reliably and confidently mastering even the most unusual requirements of an ever-changing market.

Our CarpetCablers and CarpetTwisters have been successfully used for decades to produce high quality, premium yarns for quality carpets and other textiles in the most economical way.

They offer optimum possibilities for reliably and confidently mastering even the most unusual requirements of an ever-changing market.

Optimized spindle family enables energy savings

The spindle family covers following types:

|

Dimensions [mm] |

Universal 285 |

Spindle 285 |

Spindle 260 |

Spindle 220 |

|---|---|---|---|---|

|

Feed pot package |

285 |

285 |

260 |

220 |

|

Spindle gauge |

495 |

495 |

445 |

445 |

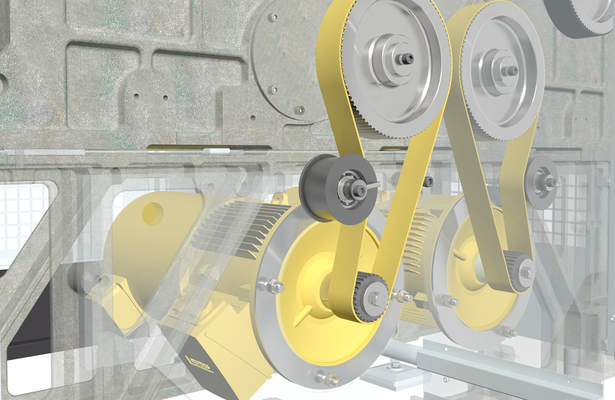

Energy savings due to energy optimized machine components

-

High class efficiency main drive motors

-

Optimized bearings in the entire spindle area

- Higher productivity by delivery speeds of up to 120 m/min when up-twisting

- Less space needed due to closer spindle spacing

- Higher production speeds due to low yarn balloon tension

Reduced machine operating time due to central adjustments

Fast, simple and precise motor-driven drive for an optimum height position.

An optimum, uniform height position on all yarn balloon guides.

Package conveyor belt to rapidly clear away the finished packages

Easy and quick yarn threading due to Volco-/Creeljet-Systems

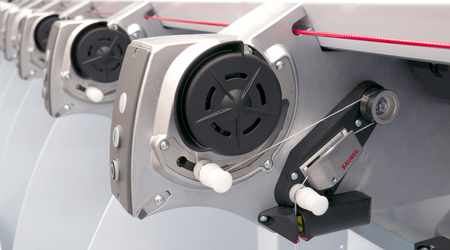

Computer-controlled electro-mechanical gearbox

Why are carpet yarns directly cabled on Saurer cabling machines?

- Cabling is a mechanical yarn upgrading process which precedes carpet production.

- Cabled yarns are ideal for ensuring the formation of a high-quality pile during the manufacture of rugs and carpets.

- In the direct cabling process, two yarns are twisted around each other in a single operation without the individual strands themselves being twisted.

Conversion of direct-cabling machine to two-for-one twisting machine

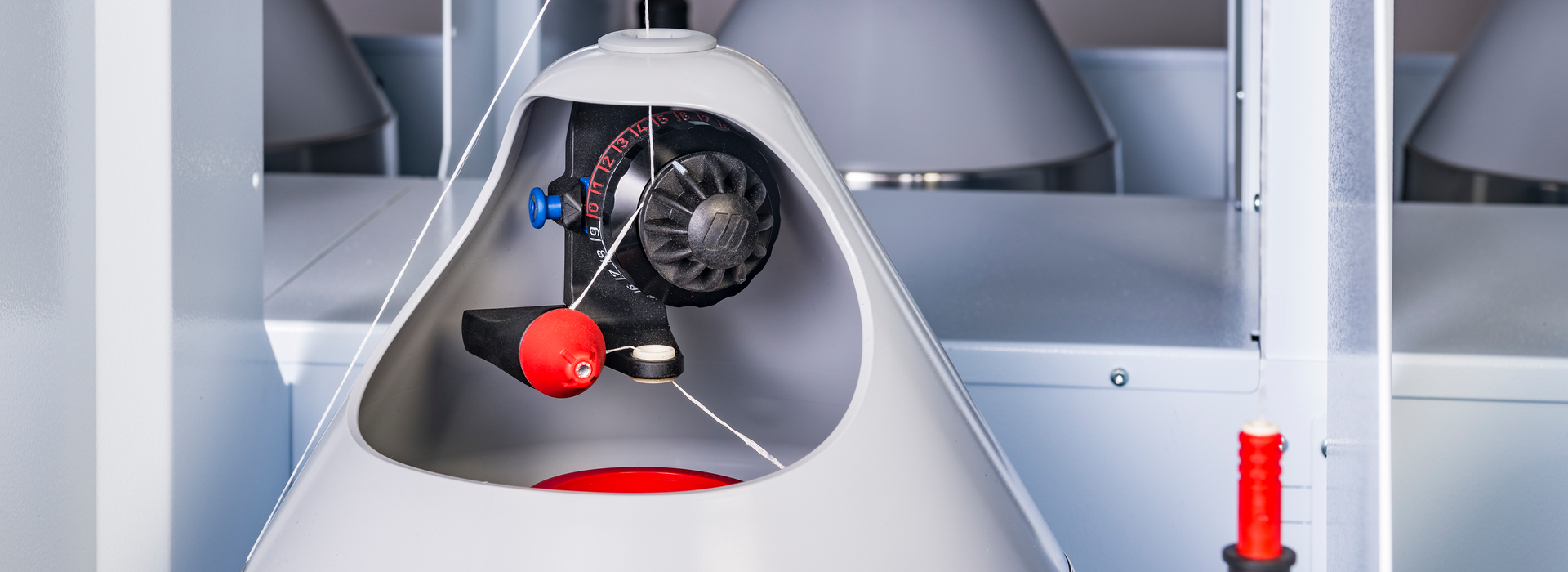

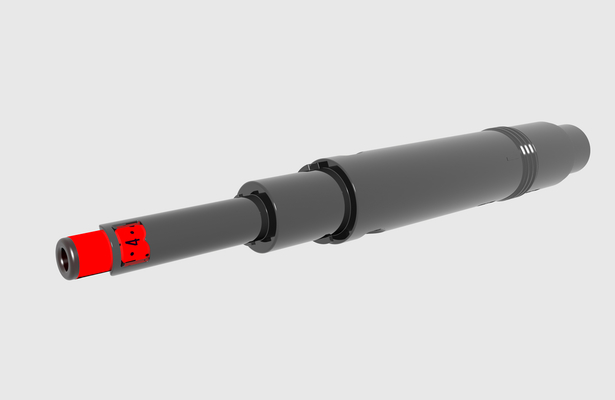

The universal hollow-shaft spindle allows the simple alternating conversion from the two-for-one method to the cabling method. The high-quality and wear-resistant surface enables a yarn guidance without damaging the strand. The ideal design of the spindle pot allows a maximum number of feed packages. The reserve disc with its wear-resistant special surface guarantees a balanced tension level in the yarn balloon.

and more...

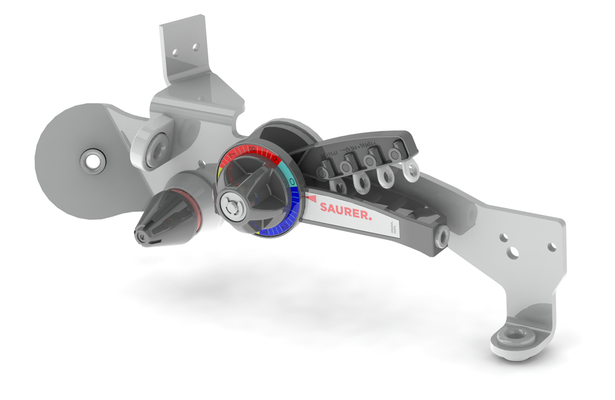

Electro-mechanical gearbox

This computer-controlled drive system is the perfect solution to the market's requirement for fast, effective adjustment to a new yarn batch, accompanied by increased machine availability. The dual cam gearbox with solid electric motor drive in connection with frequency inverters guarantees a fast change of batch and optimum utilisation of your machine.

Ball yarn brake in spindle pot

The ball yarn brake covers the entire yarn tension range with the wear-resistant ceramic ball. A simple turn of the inlet tube quickly adjusts the braking force over 24 levels.

Picture gallery

Related articles

Here you will find further information – for example application reports, customer success stories and interviews – about the above product.

Downloads

Find out more about our products. Here we provide you with all the relevant documents for download in PDF format.

CarpetCabler/CarpetTwister product brochure EN

4.49 MB

CarpetCabler/CarpetTwister product brochure DE

4.01 MB

CarpetCabler/CarpetTwister product brochure ZH

4.63 MB

CarpetCabler/CarpetTwister product brochure IT

4.12 MB

CarpetCabler/CarpetTwister product brochure RU

4.02 MB

Carpet Cabler/Carpet Twister product brochure TR

4.01 MB

Strong and reliable life-cycle partnership.

Unique smart solutions to increase the benefit to the customer.

Notable performance and sustainability throughout the machine lifetime.

We keep you competitive.

Senses

With a single program, you can now manage your Saurer machines. Senses bundles and analyzes production, quality and performance data. Secure and from everywhere.