Senses Shop Floor

Advanced shop floor.

With the Senses Element Shop Floor you can optimize your production facility by shorteningthe distances for your operators. Senses Shop Floor ensures that all relevant information is made transparent for the operator in our Senses system.

The empty can information for the open end spinning machines let the operator know when a can runs out and must be replaced. The doff preview shows the operator where the next doff will happen.

With the Senses Element Shop Floor you can optimize your production facility by shorteningthe distances for your operators. Senses Shop Floor ensures that all relevant information is made transparent for the operator in our Senses system.

The empty can information for the open end spinning machines let the operator know when a can runs out and must be replaced. The doff preview shows the operator where the next doff will happen.

Features and benefits

- Dashboard for doff preview

Senses shows the operator where the next doff will be - Dashboard for can preview

Overview where the next material is needed - Display of information in production

Possibility to show the relevant information on Smart- or I-TV in the production - Better planning of operator workload

With the information where the operator and the raw material will be needed, the workload for the operator decreases - Increase of productivity

Senses informs the operator on early stage where to be and the unproductive time will be reduced because of missing material or operator - Guidance of material train

Senses can guide the material train driver with a mobile device

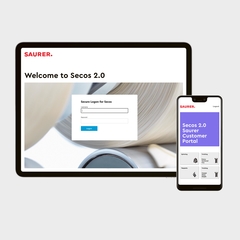

Can preview

The can preview shows the Senses user an overview of when and where the next can changes are due.

The table shows in how many minutes / hours the operator has to change the can at which machine and position.

The timeline gives a graphical overview of how many cans have to be replaced in which period of time. The Senses user can determine from which parallel number of cans it becomes time-critical and can have this individually marked in color, e.g. here in the picture from two parallel can changes (marked in orange).

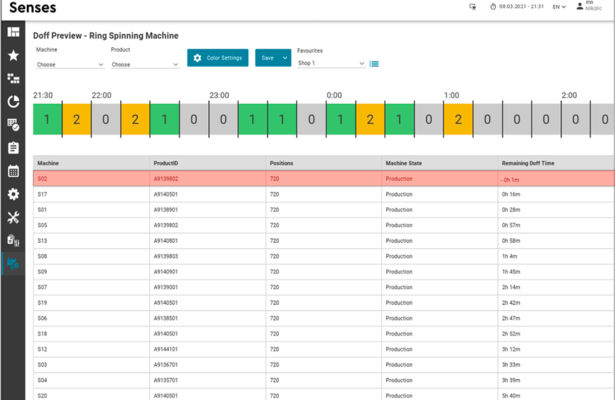

Doff preview

The doff preview gives the operator an overview of when and where the next doff will take place.

The table provides information about the number of minutes / hours in which the operator must be at which machine and position in order to carry out the doff.

The timeline shows how many doffs take place in which period. The Senses user can determine from which parallel number of doffs it becomes time-critical and can have this individually marked in color, e.g. here in the picture from two parallel doffs (marked in orange).

Areas of application

Available for Saurer machines (special software version must be installed)

Roving: Starting from machine generation 670Ringspinning: Starting from machine generation 351Rotorspinning: Starting from machine generation ACO 8Airspinning: Starting from machine generation Autoairo

Picture gallery

Impressions of Senses Elements Shop Floor.

Downloads

Find out more about our products. Here we provide you with all the relevant documents for download in PDF format.

Fact Sheet Senses Shop Floor EN

1.91 MB

Senses

With a single program, you can now manage your Saurer machines. Senses bundles and analyzes production, quality and performance data. Secure and from everywhere.

Strong and reliable life-cycle partnership.

Unique smart solutions to increase the benefit to the customer.

Notable performance and sustainability throughout the machine lifetime.

We keep you competitive.

Digital Team

Should you have questions about Senses, Senses Elements, the Calculator App or require additional guidance, kindly get in touch with our Digital team. As your partner, we pride ourselves in providing expert and swift support. You can reach us at info.senses@saurer.com.