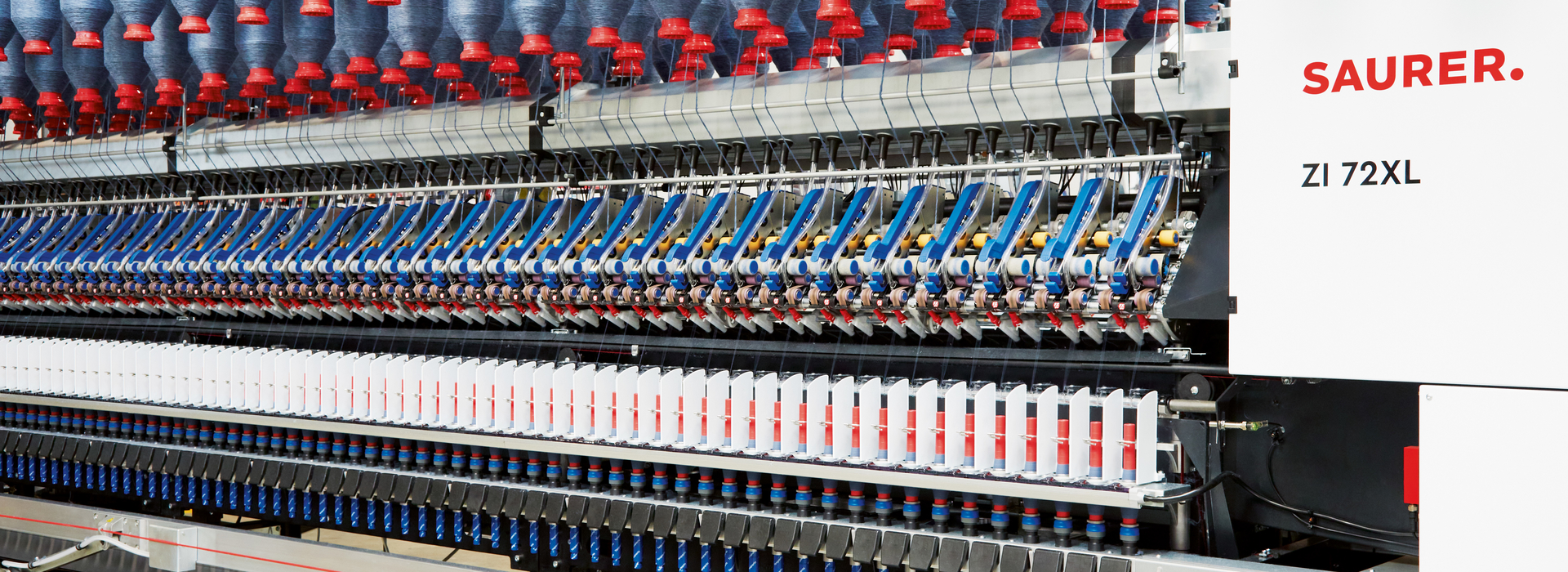

Compact-spinning machine

ZI 72XL

Be modular.

Individual challenges demand individual solutions. Discover the new ZI 72XL that adapted 100% to your needs. Modularly equipped with the drafting system drive of your choice and, depending on the application, the appropriate compact system, a flexible fancy yarn system and other advanced technologies.

Individual challenges demand individual solutions. Discover the new ZI 72XL that adapted 100% to your needs. Modularly equipped with the drafting system drive of your choice and, depending on the application, the appropriate compact system, a flexible fancy yarn system and other advanced technologies.

E³: our development philosophy

The needs of our customers are our top priority. With every new or further development, we pay attention to reducing energy consumption, increasing efficiency and improving ergonomics. The E³ philosophy underlies all our designs and our smart solutions provide added value to customers. With the transformation of the textile industry for the Circular Economy, the processing of sustainable fibres is another important focus point in our developments.

- Powerful and economical drive technology

- Low energy costs thanks to Twinsuction and Optisuction

- Energy monitoring for maximum cost transparency

- Top speeds and lowest yarn break rates

- Maximum productivity for commodity and specialist applications

- More productivity per m²

- Simple, intuitive operation through Easyspin

- Spinnfinity eliminates wharve cleaning

- Made-to-measure automation

Highlights ZI 72XL

- E³ certified

- Modular machine concept

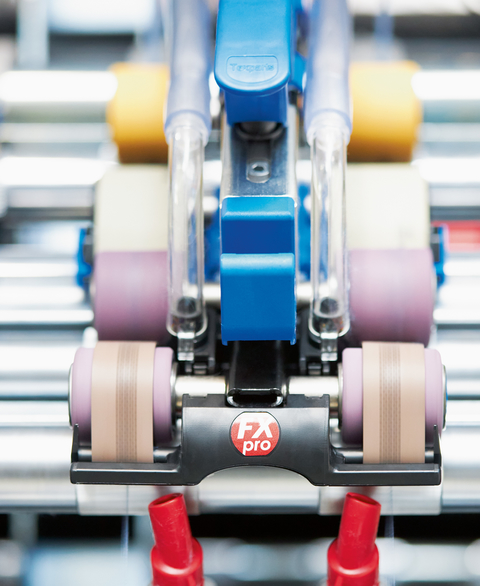

- Impact FX pro compact system for high-quality yarns

- Encapsulated electronically controlled drafting system drive Draftbox with adjustable break draft

- Intelligent speed maximisation with Optispeed

- User-friendly individual spindle monitoring (ISM)

Impact FX pro: the new benchmark in compact spinning

With the new Impact FX pro, Saurer is launching a second compact yarn system on the market and offering its customers maximum flexibility.

Impact FX pro particularly demonstrates its strengths in the medium and fine yarn count range and produces impressively compact yarns with low hairiness and high tenacity. With the new Impact FX pro, Saurer is reinforcing its status as a long-established compact yarn specialist and setting the benchmark for perfect quality yarns with a focus on the downstream processing stages.

- High-quality compact yarns for medium and fine counts

- Unique self-cleaning technology

- Up to 25% less hairiness

- Up to 2,5 cN/tex higher tenacity

- Guaranteed compacting power thanks to separate vacuum unit

- Lower spinning costs as a result of optimal raw material utilisation

- Using one system for different compact yarn quality

Picture gallery

Impressions of the ZI 72XL.

Spotlight on sustainability

Autospeed and ZI 72XL

Impact FX and Impact FX pro

Compact flexibility

Z 72XL

Benchmark for intelligent and sustainable ring spinning

70 years ring spinning

Intelligent ring spinning solutions.

Related articles

Here you will find further information – for example application reports, customer success stories and interviews – about the above product.

Downloads

Find out more about our products. Here we provide you with all the relevant documents for download in PDF format.

ZR 72XL/ZI 72XL product brochure EN

7.68 MB

Senses

With a single program, you can now manage your Saurer machines. Senses bundles and analyzes production, quality and performance data. Secure and from everywhere.

Strong and reliable life-cycle partnership.

Unique smart solutions to increase the benefit to the customer.

Notable performance and sustainability throughout the machine lifetime.

We keep you competitive.