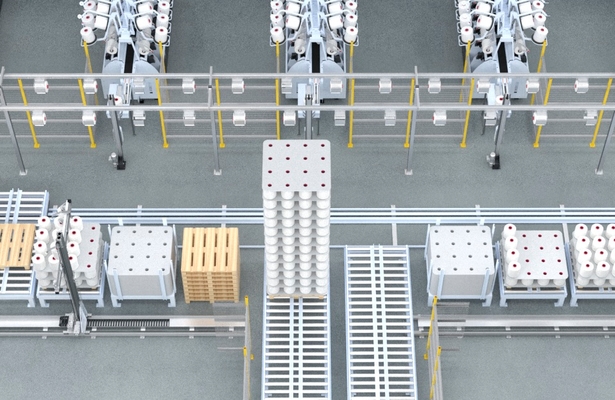

Palletiser

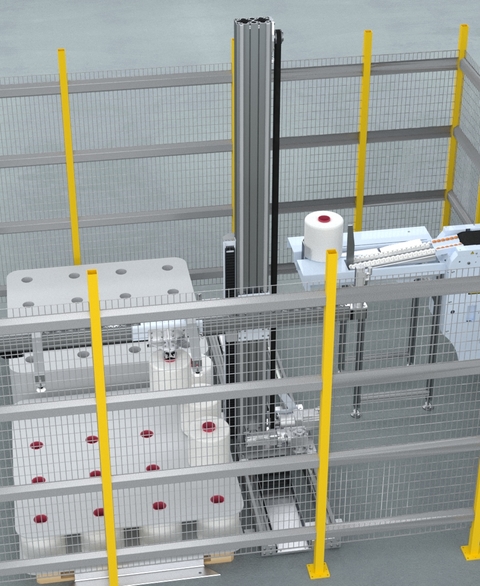

The palletising systems are developed for the cost and time saving loading of pallets with cylindrical or conical cross-wound packages while preserving the yarn quality.

For this purpose, each machine or, in case of the central palletiser, each conveyor is equipped with a package preparation device for orienting and centering the cross-wound packages. After preparing the cross-wound packages, a palletising robot with a gripper can efficiently unload the packages and store them on the dedicated pallet. These pallets are aligned on the floor and handled either by the operator manually or by a semi- or full-automatic system. Depending on the number of machines, separator magazines are integrated to place these on the pallet and between the different yarn layers. These magazines must also be filled either by the operator manually or by semi- or full-automatic system.

Advantages

- Increase quality and productivity

- Less labour costs

- Low investment

The palletising systems are developed for the cost and time saving loading of pallets with cylindrical or conical cross-wound packages while preserving the yarn quality.

For this purpose, each machine or, in case of the central palletiser, each conveyor is equipped with a package preparation device for orienting and centering the cross-wound packages. After preparing the cross-wound packages, a palletising robot with a gripper can efficiently unload the packages and store them on the dedicated pallet. These pallets are aligned on the floor and handled either by the operator manually or by a semi- or full-automatic system. Depending on the number of machines, separator magazines are integrated to place these on the pallet and between the different yarn layers. These magazines must also be filled either by the operator manually or by semi- or full-automatic system.

Advantages

- Increase quality and productivity

- Less labour costs

- Low investment

Single palletiser

300 pkgs/hr/machine and to handle up to 5 different lots.

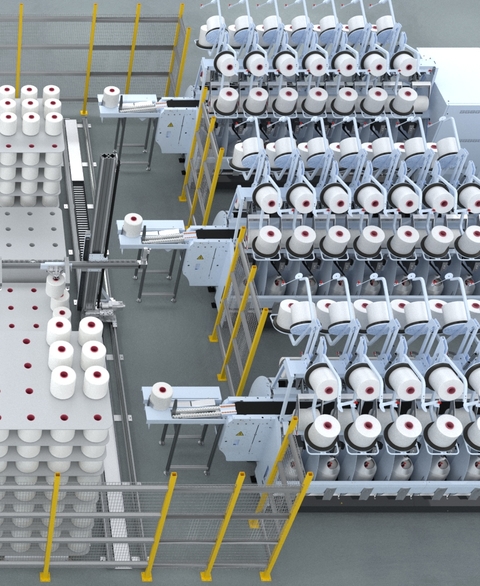

Group palletiser

The group palletiser is installed directly behind a group of twisting machines.

It can be used when an efficient use of a single palletiser is not applicable. Then the group palletiser can unload several machines and store the cross-wound packages to dedicated pallets.