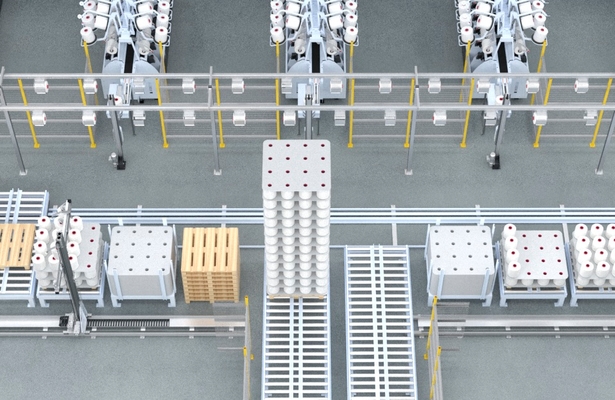

Palettierer

Die Palettiersysteme sind für die kosten- und zeitsparende Bestückung von Paletten mit zylindrischen oder konischen Kreuzspulen bei gleichzeitiger Bewahrung der Garnqualität entwickelt worden.

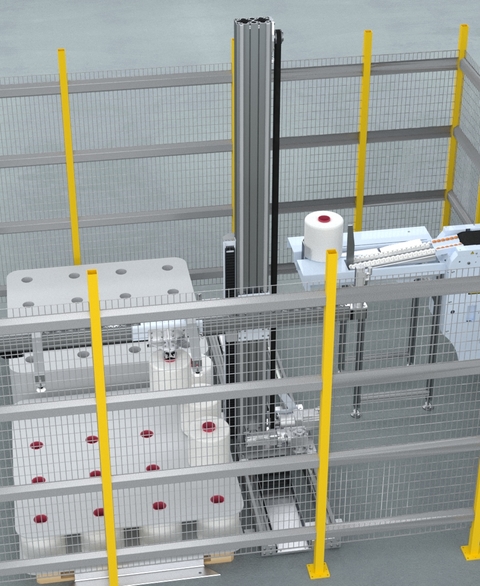

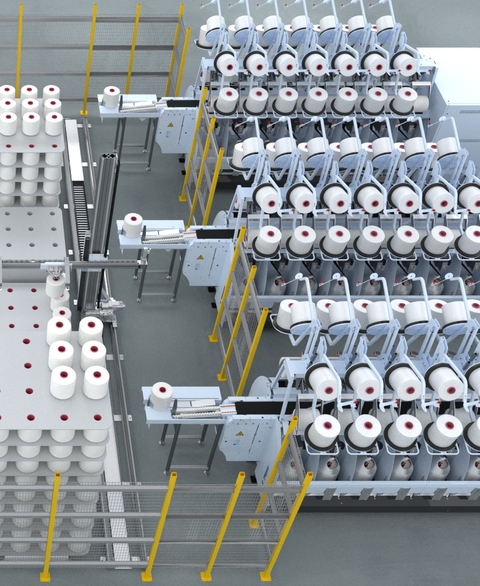

Jede Maschine bzw. beim Zentralpalettierer jedes Förderband ist mit einer Spulenvorbereitungseinrichtung zum Ausrichten und Zentrieren der Kreuzspulen ausgestattet. Nach der Spulenvorbereitung kann ein Palettierroboter die Spulen effizient entladen und auf der dafür vorgesehenen Palette stapeln. Diese Paletten sind auf dem Boden ausgerichtet und werden entweder manuell durch den Bediener oder durch ein halb- oder vollautomatisches System gehandhabt. Je nach Anzahl der Maschinen sind Magazine mit Zwischenlagen vorgesehen, um die Zwischenlagen sowohl auf der Palette als auch zwischen die verschiedenen Garnlagen platzieren zu können. Die Magazine müssen in regelmäßigen Abständen vom Bediener manuell befüllt werden.

Vorteile

- Steigerung der Qualität und Produktivität

- Geringere Arbeitskosten

- Niedrige Investitionen

Die Palettiersysteme sind für die kosten- und zeitsparende Bestückung von Paletten mit zylindrischen oder konischen Kreuzspulen bei gleichzeitiger Bewahrung der Garnqualität entwickelt worden.

Jede Maschine bzw. beim Zentralpalettierer jedes Förderband ist mit einer Spulenvorbereitungseinrichtung zum Ausrichten und Zentrieren der Kreuzspulen ausgestattet. Nach der Spulenvorbereitung kann ein Palettierroboter die Spulen effizient entladen und auf der dafür vorgesehenen Palette stapeln. Diese Paletten sind auf dem Boden ausgerichtet und werden entweder manuell durch den Bediener oder durch ein halb- oder vollautomatisches System gehandhabt. Je nach Anzahl der Maschinen sind Magazine mit Zwischenlagen vorgesehen, um die Zwischenlagen sowohl auf der Palette als auch zwischen die verschiedenen Garnlagen platzieren zu können. Die Magazine müssen in regelmäßigen Abständen vom Bediener manuell befüllt werden.

Vorteile

- Steigerung der Qualität und Produktivität

- Geringere Arbeitskosten

- Niedrige Investitionen

Einzelpalettierer

Gruppenpalettierer