Fibrevision

Yarn monitoring and grading systems for synthetic filament yarn production:

Online monitoring is crucial for synthetic yarn production because:

- Quality Assurance:

Online monitoring allows for real-time assessment of yarn quality during the manufacturing process. - Process Optimisation:

Monitoring systems provide valuable data on various process parameters like tension, interlace dynamics and broken filaments. This can be used for statistical analysis and trend identification. - Early Detection of Problems:

Online monitoring systems can detect issues at an early stage, allowing for timely intervention.. - Product Consistency:

Maintaining consistent product quality is vital in the textile industry. Online monitoring ensures that yarn properties, such as denier, tenacity, and elongation, remain within specified tolerances. Consistency is essential for meeting customer expectations and adhering to industry standards. - Reduced Labour Costs:

Automation of monitoring processes reduces the need for constant human supervision on the production floor. - Compliance and Reporting:

Many industries have strict quality and safety regulations. Online monitoring systems provide a digital record of the production process, which can be used to demonstrate compliance with industry standards and regulatory requirements - Customer Satisfaction:

High-quality, consistent yarn properties are essential for meeting customer expectations. Online monitoring ensures that the final product meets or exceeds customer specifications, enhancing customer satisfaction and loyalty.

Downloads

Find out more about our products. Here we provide you with all the relevant documents for download in PDF format.

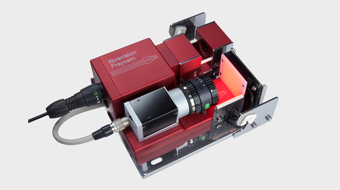

Fibrevision FrayTecFV2

1.00 MB

Fibrevision Unitens

1.81 MB

Fibrevision FibreTQS Interlace Monitoring

1.57 MB

FactSheet Fibrevision Microscan EN

1.07 MB

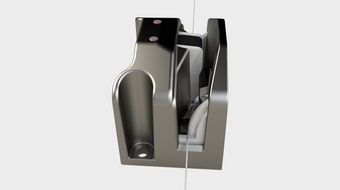

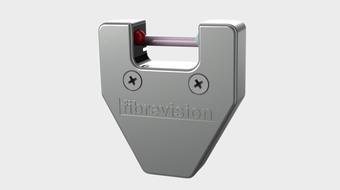

FactSheet Fibrevision LabTex EN

175.51 KB

Fibrevision FrayCam2

2.31 MB

Contact us

Should you have any questions about Fibrevision or require additional guidance, kindly get in touch with our team. As your partner, we pride ourselves in providing expert and swift support. You can reach us at +44 162 542 5355.

![Microscan_image[1]](/uploads/media/340x190/04/5674-Microscan_image%5B1%5D.jpg?v=1-0)

![LabtexImage[1]](/uploads/media/340x190/06/5616-Labtex.jpg?v=2-0)