PrimeTwister

Two-for-one twisting machine

Saurer Twisting Solutions offers an optimum in variability and flexibility with the two-for-one twisting machine PrimeTwister.

Saurer Twisting Solutions offers an optimum in variability and flexibility with the two-for-one twisting machine PrimeTwister.

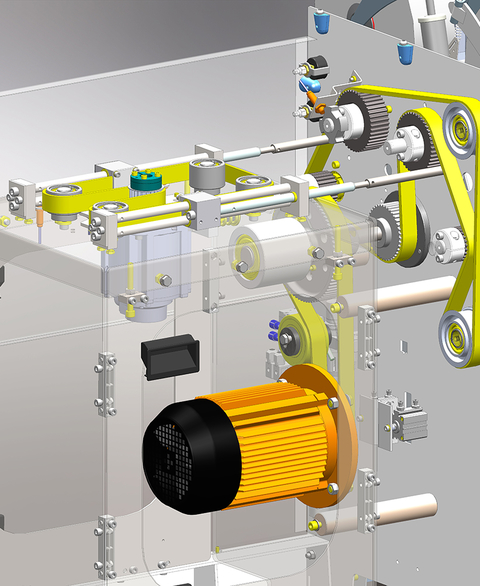

Electronic drive section with servo gearbox

Your advantages:

- Up to 30% higher productivity due to delivery speeds up to 110m/min

- Operating costs reduced thanks to low energy, space and maintenance costs

- Drive of up to 400 spindles via a common tangential belt

- Highest twist constancy in the twisted yarn when starting/stopping the machine

- Possibility of using a second, energy-optimised drive motor on long machines

- Yarn contamination avoided by consistently isolating the textile contact area from the spindle drive area

- High quality soft packages for sewing yarn

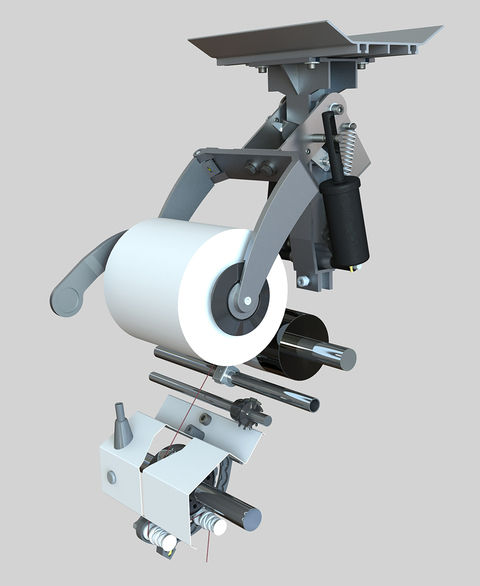

Energy efficient spindle family

The spindle types cover the yarn count range from Ne 6/2 to Ne 120/2. The twisting range extends from 110 to 2763 T/m.

VTS-10

Spindle speed up to: 13.000 U/min.

Feed package 6", Ø up to 125 mm

VTS-09

Spindle speed up to 12.500 U/min.

Feed packagee 6", Ø up to 140 mm

VTS-08

Spindle speed up to 12.000 U/min.

Feed package 6", Ø up to 160 mm

Highlights

The PrimeTwister has kept all the trusted and proven quality machine elements that come into direct contact with the yarn. Proven elements like the overfeed discs, the tailing device shaft, the traverse guides and the friction rollers have all been incorporated in the take-up area.

and more...

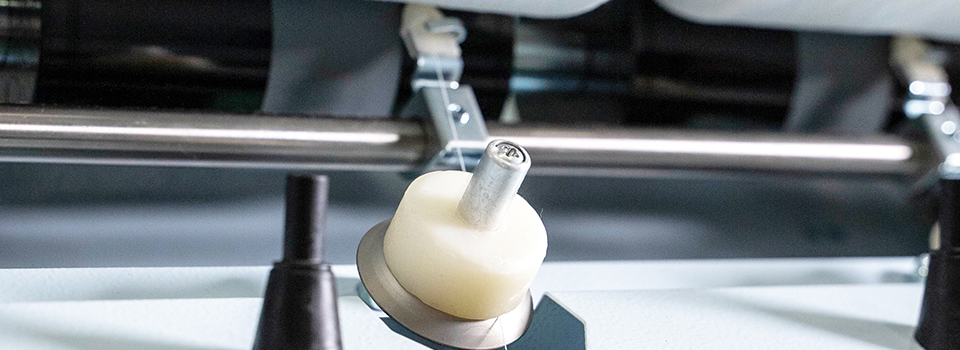

Rotating transfer-tail device

The automatic transfer-tail device allows you to set the exact length of yarn that is initially wound onto the take-up package.

Package lift-off

Following a time delay, the pneumatic package lift-off device takes the take-up package off the drive drum, avoiding any unnecessary rubbing of the package surface.

Picture gallery

Downloads

Find out more about our products. Here we provide you with all the relevant documents for download in PDF format.

2025_09_PrimeTwister_EN

3.15 MB

2025_09_PrimeTwister_ZH

3.27 MB

Strong and reliable life-cycle partnership.

Unique smart solutions to increase the benefit to the customer.

Notable performance and sustainability throughout the machine lifetime.

We keep you competitive.