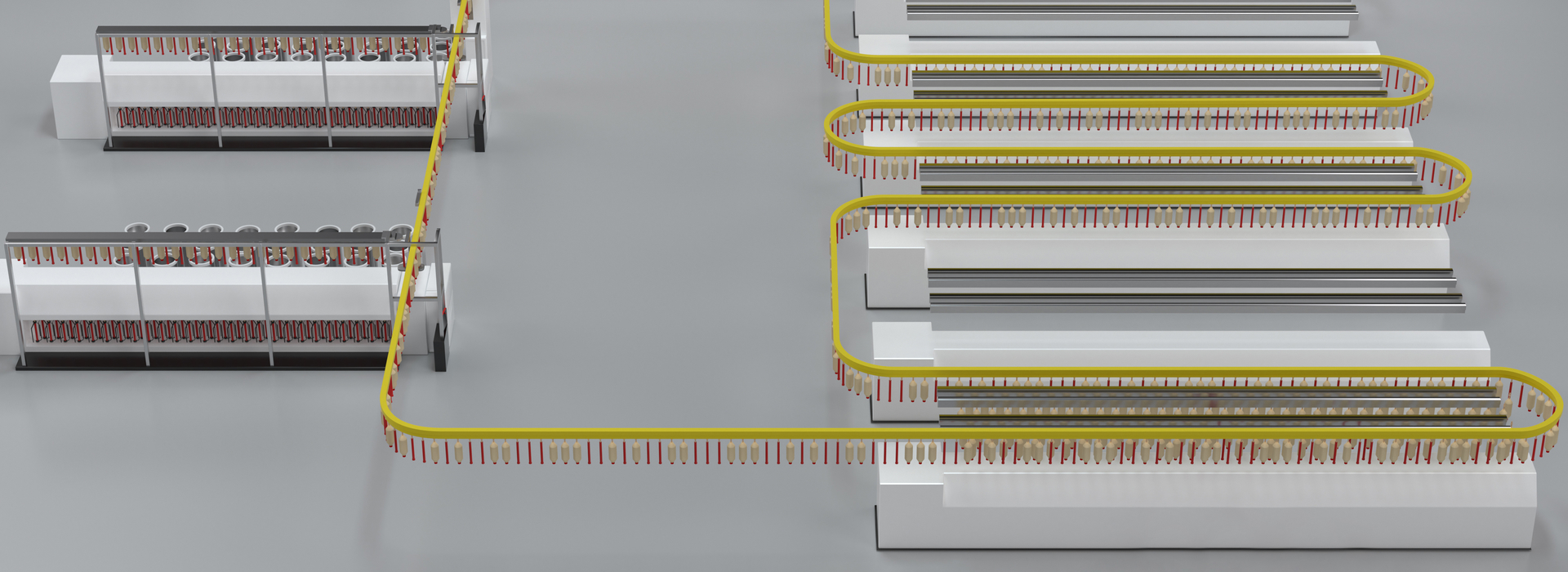

Bobbin transport system

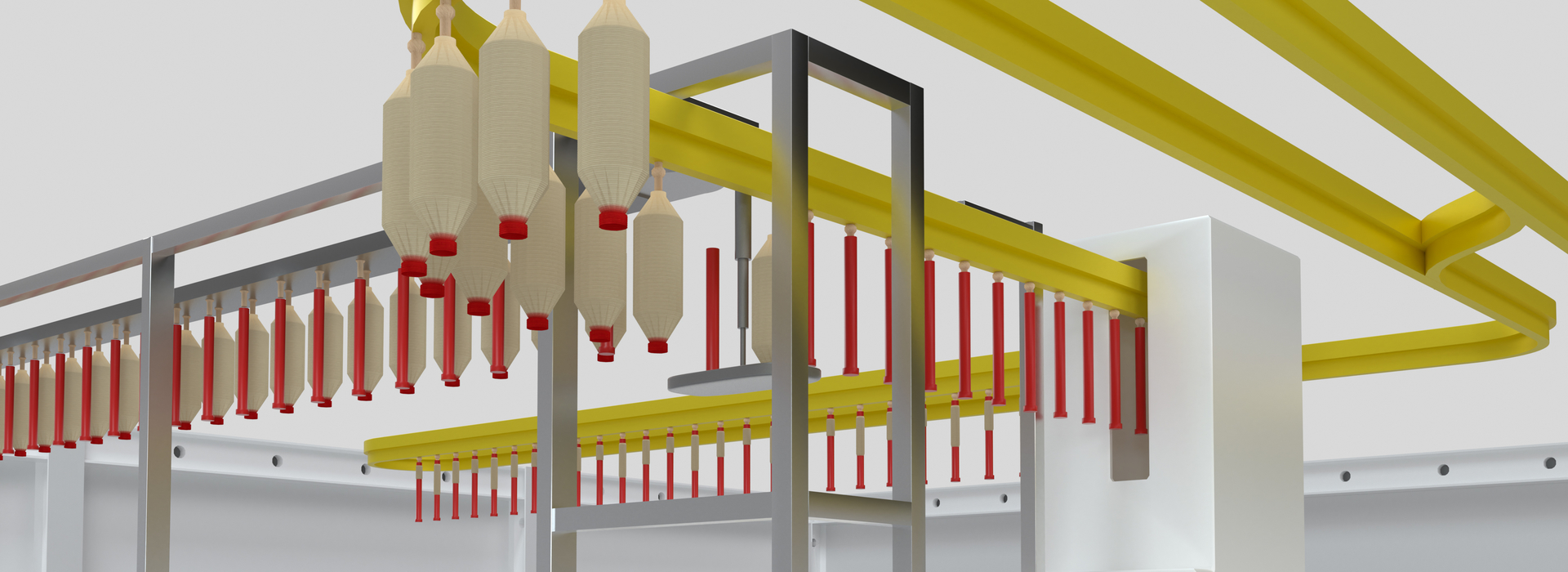

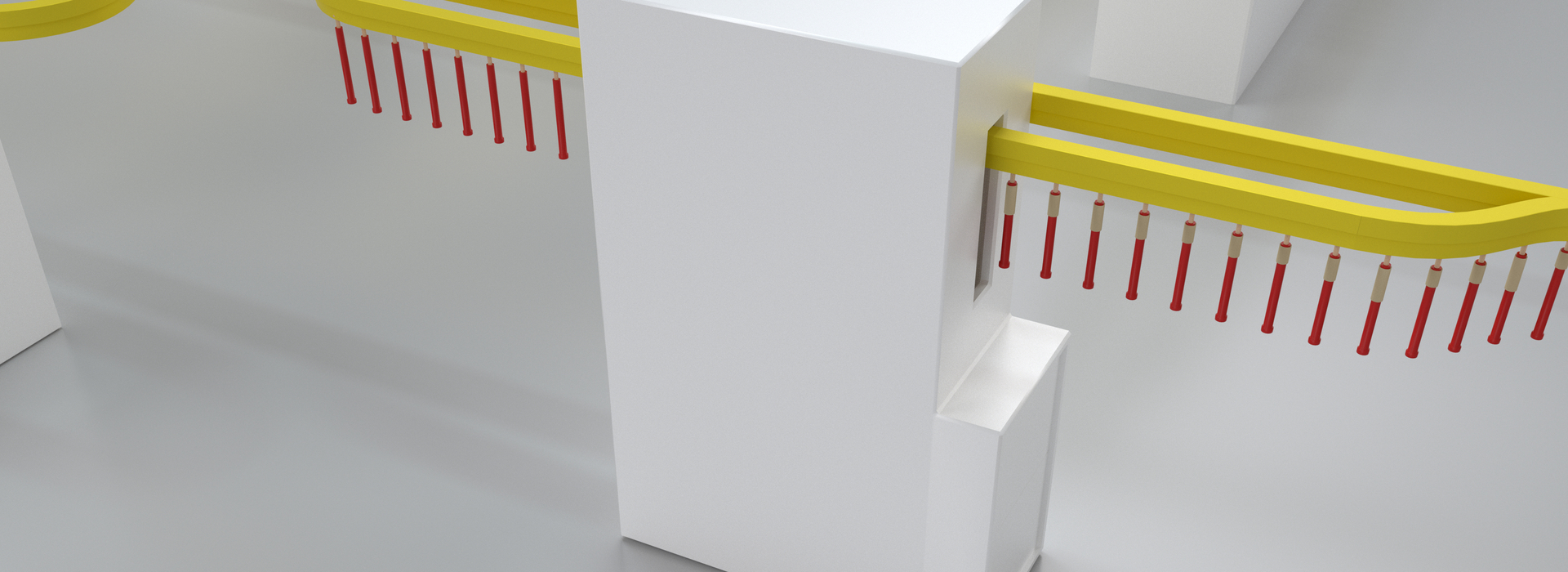

The bobbin transport system moves full roving bobbins and empty tubes between roving frame and ring spinning machine. A manual operation is possible as well as semi- or fully automatic transport solutions. The automatic tube cleaner and bobbin exchanger at roving frame afford an intelligent overall package.

The bobbin transport system moves full roving bobbins and empty tubes between roving frame and ring spinning machine. A manual operation is possible as well as semi- or fully automatic transport solutions. The automatic tube cleaner and bobbin exchanger at roving frame afford an intelligent overall package.

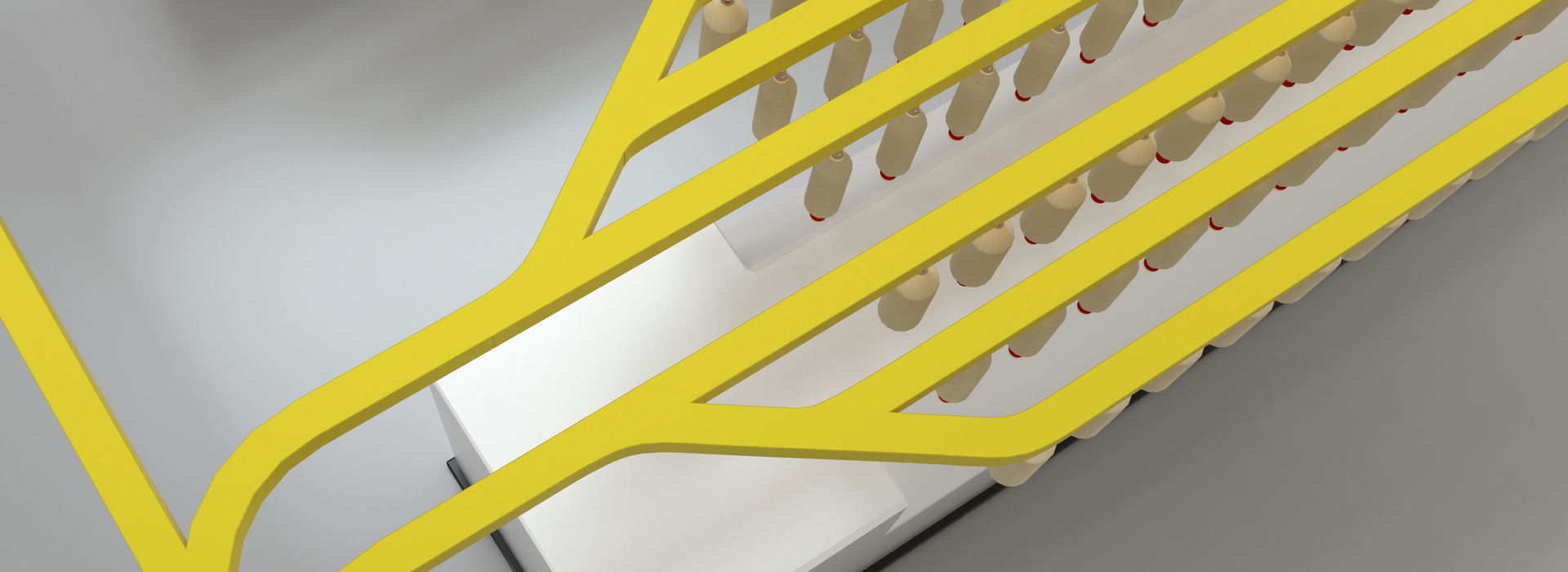

Fixflow

The securely connected circuit between roving frames and ring spinning machines moves constantly. Fixflow is best suited to your constant production with few or no article changes during maximum production.

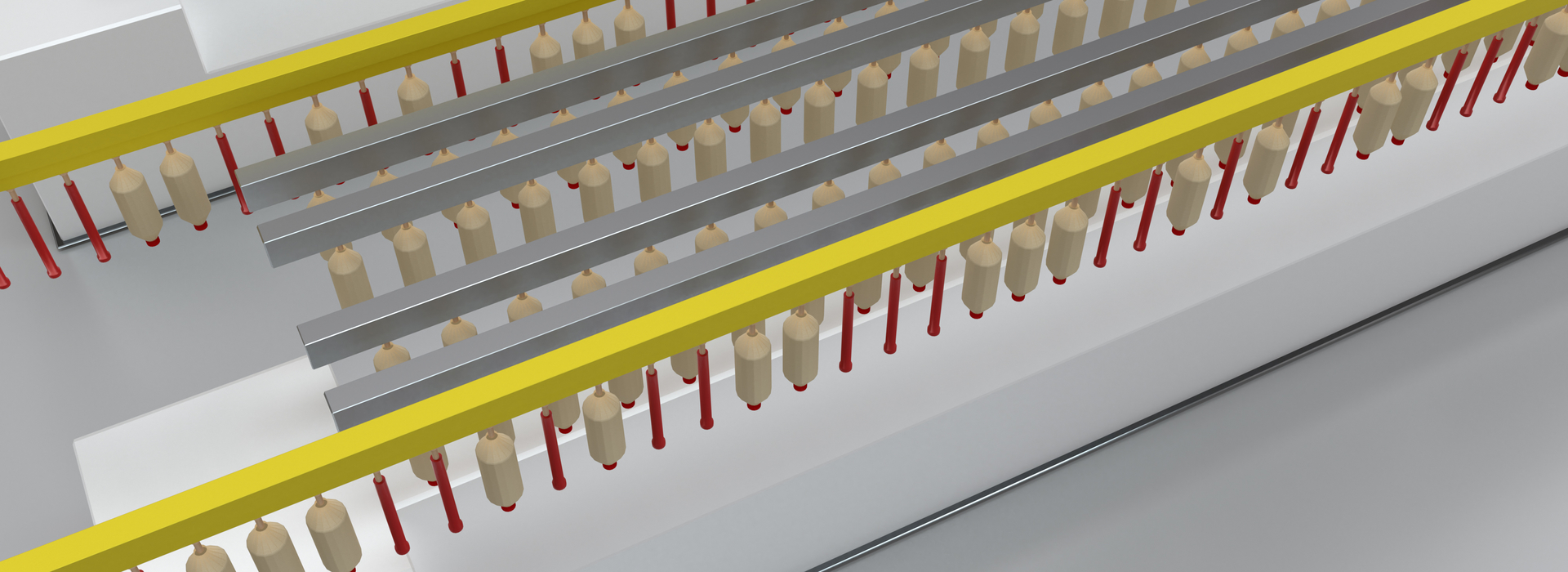

Fixflow offers a clear layout with optimum use of space as well as an easy-to-operate control system. Several roving frames can be integrated into one circuit. Different articles and lots are recognisable for the user with tubes colours, they only insert the roving bobbin into the ring spinning creel. A well organized process.

Your benefits:

- Space-saving, dynamic buffers directly at the ring spinning machine

- Clear assignment of lot and articles, preventing confusion

- Roving bobbins are removed from the continuous circuit

- Bobbin-vehicles not necessary

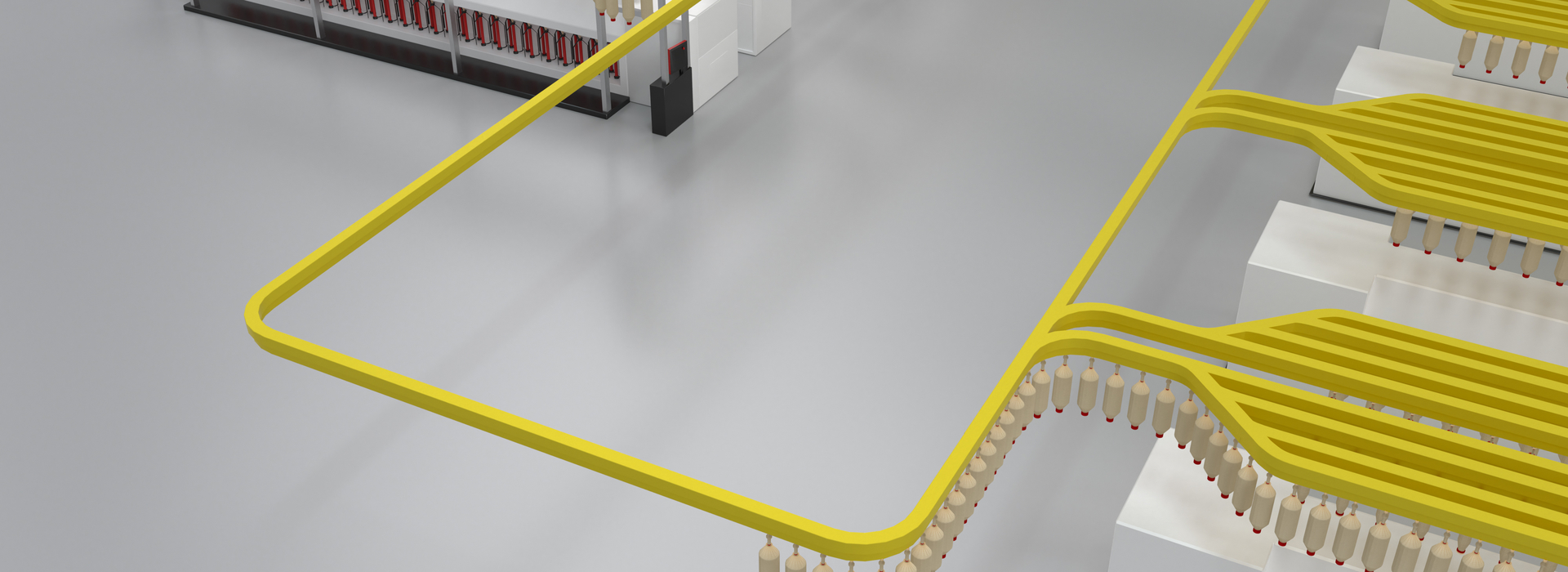

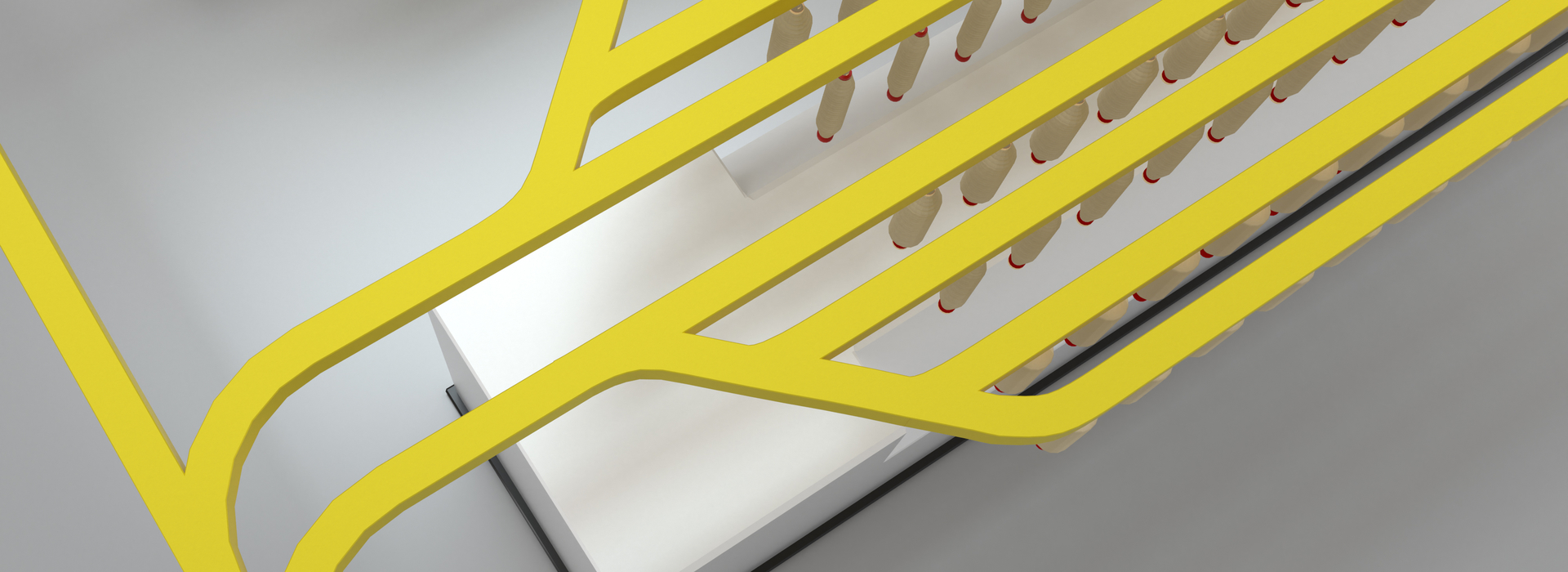

Flexflow

Flexflow is particularly suitable for changing sections, blocks or rows. Flexflow offers the maximum flexibility for a modern spinning plant. It is best suited to frequent lot changing and flexible productions plans.

Flexflow ensures smooth bobbin transfer and maximum use of your production capacity. Each roving frame can supply each ring spinning machine, different lots can be moved at the same time. With flexible integration, you have an infinite number of variation possibilities. Roving bobbins and tubes move exactly to where they are needed.

Your benefits:

- Intelligent control assigns ring spinning machines to article

- Automatic lot changing is programmable

- No material mix-up, due to different trains for each material

- System can be retrofitted and expanded

Picture gallery

Impressions of Automation.

Bakan Tex

Uzbek textile industry on growth track.

Downloads

Here we provide you with all the relevant documents for download in PDF format.