Sun – Service Unlimited

Be sunsational.

Strong and reliable life-cycle partnership.

Unique smart solutions to increase the benefit to the customer.

Nobable performance and sustainability throughout the machine lifetime.

Sun is a bundle of differentiated services that add real value to Saurer machinery throughout its entire life cycle. Highly trained staff using state-of-the-art tools improve our customers’ daily operations in a flexible and individual way. We provide the owners of Saurer machinery with innovative solutions and services to improve the product quality, machine performance and profitability.

We keep you competitive.

Saurer sets the benchmarks with:

- Consulting

- Installation

- Academy

- Original Parts

- Maintenance

- Updates and Upgrades

Strong and reliable life-cycle partnership.

Unique smart solutions to increase the benefit to the customer.

Nobable performance and sustainability throughout the machine lifetime.

Sun is a bundle of differentiated services that add real value to Saurer machinery throughout its entire life cycle. Highly trained staff using state-of-the-art tools improve our customers’ daily operations in a flexible and individual way. We provide the owners of Saurer machinery with innovative solutions and services to improve the product quality, machine performance and profitability.

We keep you competitive.

Saurer sets the benchmarks with:

- Consulting

- Installation

- Academy

- Original Parts

- Maintenance

- Updates and Upgrades

Picture gallery

Sun – Service Unlimited

We enhance performance. We power sustainability. We boost profitability.

Sun – Service Unlimited

Discover the Sun elements for a strong and reliable life-cycle partnership.

Consulting

Process optimisation, upgrade services and energy savings are part of Saurer Consulting. Our specialists are pleased to offer you a consulting package which is specifically adapted to your production requirements.

-

Upgrading your production plant

-

Increasing the economic efficiency of your machines

-

Enhancing the competitiveness via optimisation of your production processes

-

Improving the energy balance

- Process analysis and process monitoring

Textile Technology Services & Consulting

Optimise.

In our Customer Technology Centres all over the globe, you can have your materials spun to your particular specifications – and you can see it being done.

- This way you can know the potential of your future Saurer system in advance

- Take advantage of this opportunity and benefit from our consulting

- Create new perspectives with our support

- Playing it safe – the textile laboratory: In our high-tech laboratories, we combine experience with technical expertise using precise measurement data from modern analytical methods

Learn more about our Textile technology expertise: Introducing our textile laboratory.

Installation

Saurer covers everything: From before the start of the project to the maintenance and optimisation of the processes, through to subsequent expansion of productivity. What could be included: Financing, plant design and production support, among others. We work with competent, intercultural teams worldwide.

-

Fast and smooth

-

Based on applied knowledge along the entire textile process

-

Innovative due to the use of state-of-the-art technology

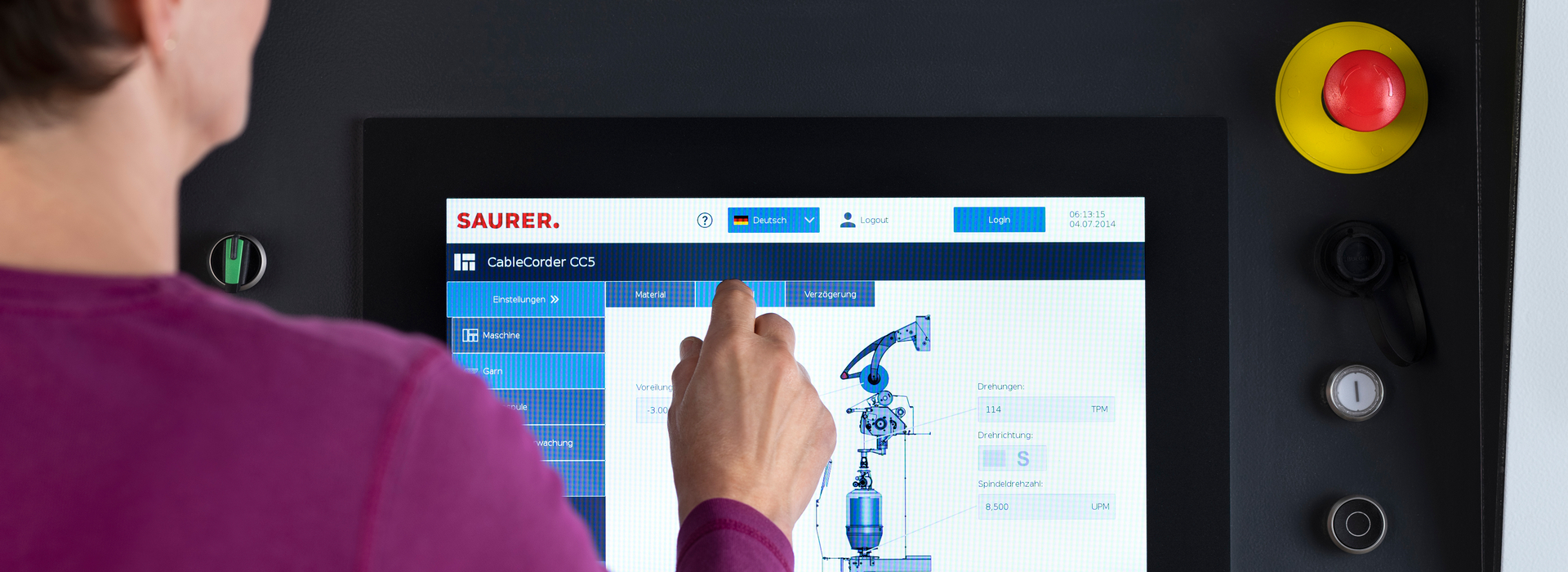

Saurer Academy

Become an expert.

Learn when and where it suits you - everywhere and at once. Become an expert with the new Saurer Academy. Motivated and optimally trained employees form the basis for the best possible operation of your installation – and thus for maximum profit.

-

Online bookings for classroom and web-based training sessions

- e-learning with informative training materials such as animations, videos, flash cards,web-based training (WBT) sessions and courses in a virtual classroom (VC)

Original Parts

Be competitive.

Only original parts possess the know-how that uses the full potential of your machine. They have been thoroughly tested by us in hardness applications and prove their value a thousand-fold in spinning mills worldwide. You can easily recognise them by the Saurer quality seal.

Saurer Original Parts offer:

- Specified guarantee and warranty period

- Information concerning expected service life and application recommendations

- Reliable, fast delivery with stockkeeping in many countries

- Global technological consultancy, spinning tests and fibre checks via our Customer Technology Centres

- Order your original parts conveniently online in our Secos Customer Portal

Maintenance

On-site, by your side

Preventive maintenance lowers your costs The maintenance of a machine seems to be a cost factor only on the surface. Quite the contrary is true: Regular maintenance, which is in line with your individual requirements, lowers operating costs on a long-term basis. The maintenance expense will be kept as low as possible. This saves you time and keeps your machine at a high efficiency level over time.

- We are available around the clock, regardless of production site

- You benefit from a worldwide network of Customer Service Centres with one close to you: There our specialists perform repairs on-site or exchange electronic components, for instance

- With the Senses Maintenance, you can digitalise the maintenance process for your machines. You can plan, conduct and document the maintenance of your machines quickly and efficiently—even for machines from third party providers

Updates and Upgrades

Always state of the art

Technology does not stand still – the innovative updates and upgrades offered by us ensure that you never fall behind with your Saurer machine. Further technical and technological developments to increase productivity and yarn quality can be integrated into existing machine installations at any time. Our kits pay for themselves within shortest time.

- Constructional changes of individual parts or subassemblies

- Retrofitting of new subassemblies or new parts

- Exchange of individual parts or components

- Software upgrades

Contact us

If you have any questions or want advice on anything else, please reach out to your local contact. We will be happy to support you as expert partners, responding rapidly to your requests and inquiries. You can reach us at

service.spinning@saurer.com

service.twisting.kr@saurer.com