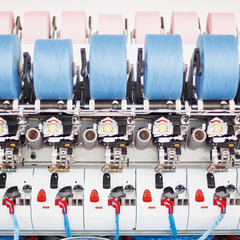

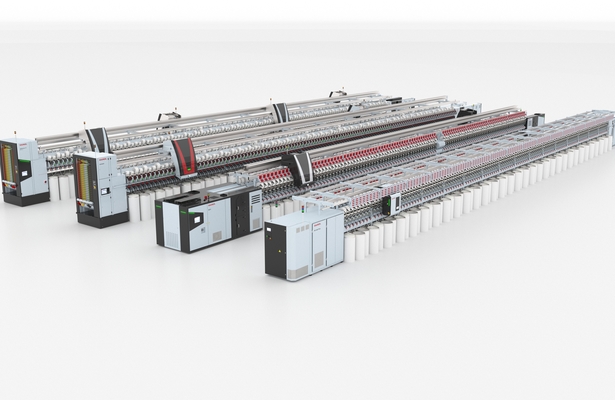

BD 480 Plus

Semi-automatic rotor spinning machine

Get even more.

The BD rotor spinning technology is worldwide the first choice in this segment. The latest generation of the BD 480 Plus is more energy- efficient, more productive and has better yarn quality than ever before.

The BD rotor spinning technology is worldwide the first choice in this segment. The latest generation of the BD 480 Plus is more energy- efficient, more productive and has better yarn quality than ever before.

E³: our development philosophy

The needs of our customers are our top priority. With every new or further development, we pay attention to reducing energy consumption, increasing efficiency and improving ergonomics. The E³ philosophy underlies all our designs and our smart solutions provide added value to customers. With the transformation of the textile industry for the Circular Economy, the processing of sustainable fibres is another important focus point in our developments.

- More efficiency with new doffing unit (DU)

- Highly efficient energy-saving

- More productivity per square meter

- Lower spinning costs

- Easy operation and maintenance

Highlights

- Automatic doffing unit (DU) for higher efficient and lower personnel requirements

- Energy saving up to 29% per kilogram of yarn thanks to new air system

- Up to 512 spinning units for more productivity

- Compact machine design for maximum productivity per square meter

- Optimized spin box structure for higher spinning stability and good yarn quality

- Fully automatic run-up with proven “Joint Spinning In” technology

- Digital yarn quality control with Corolab Q

- Coarse yarns up to Nm 1.7 / Ne 1

- Integrated fancy yarn device Fancynation for slub yarn production

- Senses for analysing all spinning data in one program – in real time, safely and from anywhere

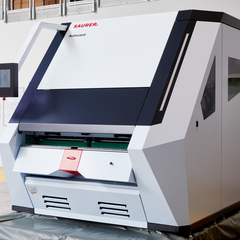

New automatic doffing unit (DU)

The BD 480 Plus with up to two doffing unitsensures high efficiency and lower personnelrequirements. The full packages can be changedautomatically with no interruption to the spinningprocess. Your operators are unburdened andavailable for new tasks.

- Personnel saving

- Doffing on the fly

- Maximum doffing efficiency

- Precise package length with the define tolerance

Picture gallery

Impressions of the BD 480 Plus

BD 480 Plus

New doffing unit (DU)

BD 480 Plus

Get even more.

Schlafhorst Systems rotor spinning

Schlafhorst Systems offer the highest versatility in the market. Whether an application requires the uniqueness and productivity of air spinning or the smart flexibility of rotor spinning, we have the solution for you. Starting from the blow room and carding, the Schlafhorst Systems are designed to ensure the excellent utilization of any kind of fibre.

Downloads

Find out more about our products. Here we provide you with all the relevant documents for download in PDF format.

BD 480 Plus Product brochure EN

2.77 MB

Related articles

Here you will find further information – for example application reports, customer success stories and interviews – about the above product.

Senses

With a single program, you can now manage your Saurer machines. Senses bundles and analyzes production, quality and performance data. Secure and from everywhere.

Strong and reliable life-cycle partnership.

Unique smart solutions to increase the benefit to the customer.

Notable performance and sustainability throughout the machine lifetime.

We keep you competitive.