Allma Systems

Industrial yarn twisting

As a market and innovation leader, we see it as our duty to offer our customers solutions with which they can confidently meet the challenges of the future. Allma Systems comprises a wide range of specialised industrial yarn twisting technologies. When an application requires intelligent and economical yarn processing, customers can rely on us for solutions that address their individual needs. We combine innovative technology with decades of experience, ensuring the excellent utilisation of any kind of yarn.

As a market and innovation leader, we see it as our duty to offer our customers solutions with which they can confidently meet the challenges of the future. Allma Systems comprises a wide range of specialised industrial yarn twisting technologies. When an application requires intelligent and economical yarn processing, customers can rely on us for solutions that address their individual needs. We combine innovative technology with decades of experience, ensuring the excellent utilisation of any kind of yarn.

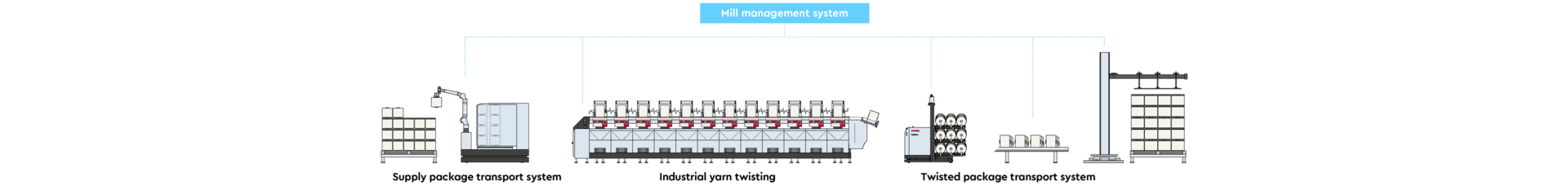

Process line for industrial yarn twisting

Your benefits

- Effective cost control, strong financial planning security, coordinated and fast installation, high level technical and technological services

- Maximum economic efficiency and quality thanks to state-of-the-art technology

- Full quality and production data control and transparency

- Comfortable and common HMI display

- Versatile and individual solutions possible

Industrial yarn

Industrial yarns are used in very different fields of application of our environment. As manifold as the applications are, as high are the demands placed on the production technology for industrial yarns. Modern systems for industrial yarns must not only enable first-class yarn quality, but also high productivity, flexibility and perfect automation. The two-for-one twisting machine TechnoCorder TC2 is a high-performance machine for twisting single and multiple yarns from a multitude of supply materials in a very wide range of yarn counts.

With Allma Systems Saurer offers you a process chain that is precisely tailored to your needs. We invite you to take advantage of this comprehensive solution.

Typical industrial yarn applications

- Protective twist

(Canvas covers, airbag, safety belts) - Mechcanical Rubber Goods

(Driving belt, air suspension bellows, tubes, conveyor belts) - Tire cord

(Chafer, cap ply, hybrid cord) - Ropes, cords, nets

- Baler twins

- Artificial turf

- Sewing thread

Your Saurer products for the production of industrial yarn

|

Process |

Saurer product |

|

|

Supply package transport system |

|

|

|

Industrial yarn twisting |

|

|

|

Twisted package transport system |

|

|

|

Mill management |

|

Strong and reliable life-cycle partnership.

Unique smart solutions to increase the benefit to the customer.

Notable performance and sustainability throughout the machine lifetime.

We keep you competitive.

Senses

With a single program, you can now manage your Saurer machines. Senses bundles and analyzes production, quality and performance data. Secure and from everywhere.