CompactTwister

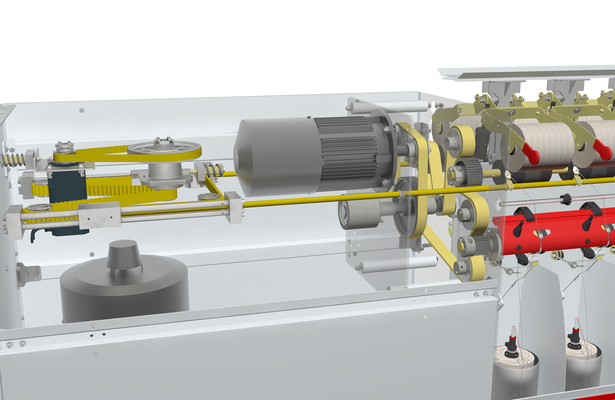

Two-for-one twisting machine

The CompactTwister has been established in the market for over 25 years. The latest generation, the series 8, once again sets new standards for the quality of twisted yarn, flexibility, energy consumption, robustness, lower space requirement and ease of maintenance.

Nearly 5 million supplied spindles demonstrate its leading position on the market. Thanks to innovative development and the latest production methods, the CompactTwister offers high efficiency combined with excellent quality of the cross-wound delivery packages produced.

The CompactTwister has been established in the market for over 25 years. The latest generation, the series 8, once again sets new standards for the quality of twisted yarn, flexibility, energy consumption, robustness, lower space requirement and ease of maintenance.

Nearly 5 million supplied spindles demonstrate its leading position on the market. Thanks to innovative development and the latest production methods, the CompactTwister offers high efficiency combined with excellent quality of the cross-wound delivery packages produced.

Energy saving by optimized spindle technology

Energy saving family of spindles:

- VTS-07

- VTS-08

- VTS-09

- VTS-10

Savings due to energy optimized machine components

- High class efficiency main drive motors

- Spindle belt with lowest possible energy consumption

- Optimized belt guide rollers with lower energy consumption and reduced noise emission

- Optimized bearings in the entire spindle area

Higher productivity due to delivery speeds of up to 120 m/min.

- Delivery speeds up to 120 m/min.

- Amount of twist can be set at any level

- Flanged-bobbin form, traverse and traverse variation can be adjusted individually

- Electronically controlled anti-patterning device

- Oil-free, easy maintenance construction

Less time needed to operate the machines thanks to central settings

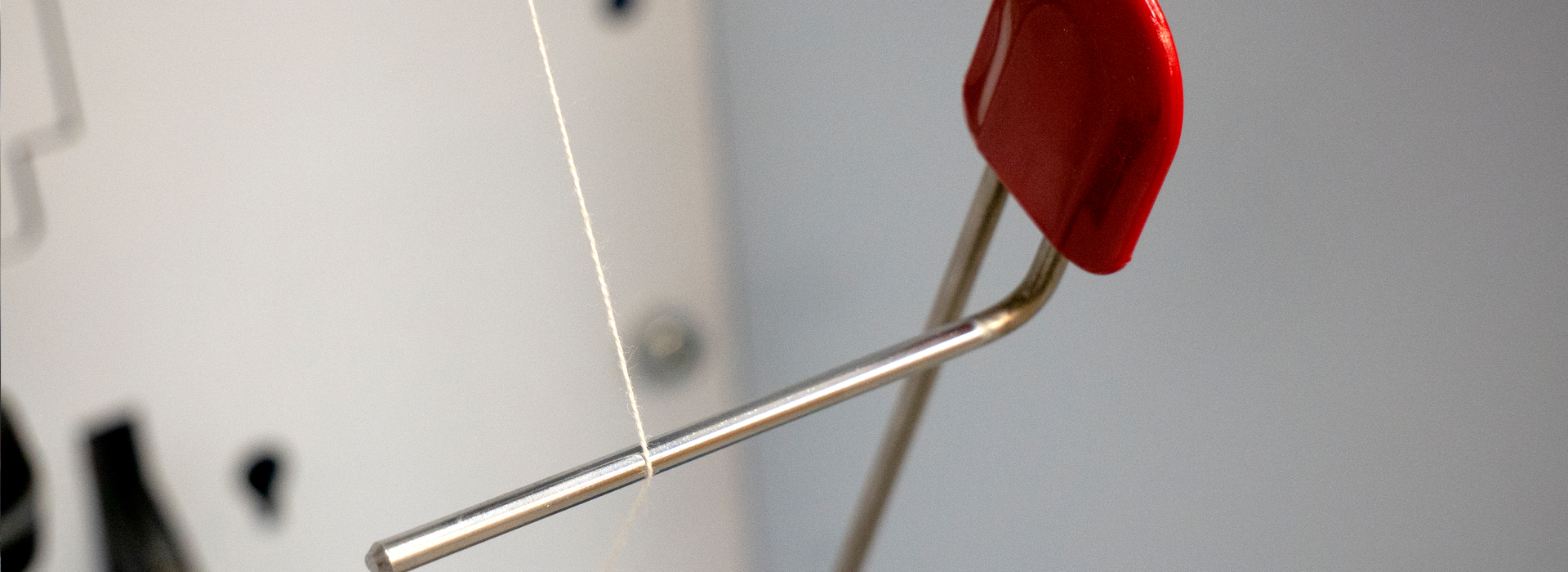

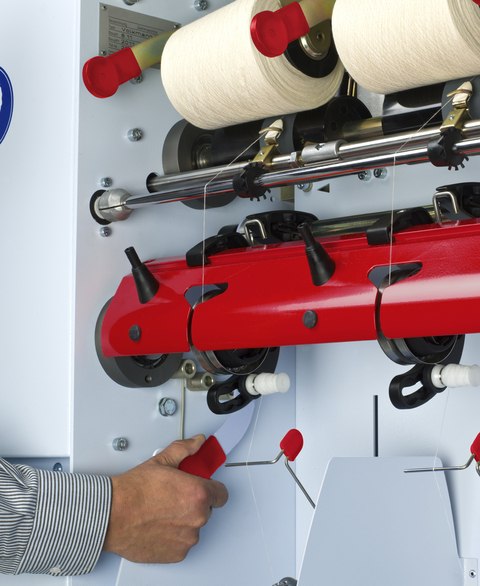

Yarns can be quickly and easily threaded via the Volcojet system

Further numerous optional handling aids:

- The automatic transfer-tail device enables a central adjustment

- Creel and storage facilities for packages and empty tubes

- Package conveyor belt

- Automatic yarn stop feeler lock

Novelties

Quality sensor

Our latest generation of quality sensor takes the testing of your yarn to a new level. By combining intelligent software and innovative evalution technology, the new quality sensor generates the best possible results for your yarn quality.

The quality sensor always provides the right basis to increase significantly the quality standard of your yarn.

and more...

The electronic drive was designed to meet the highest requirements.

- Delivery speeds up to 120 m/min

- Amount of twist level can be set at any level

- Flanged-bobbin form, traverse and traverse variation can be adjusted individually

- Electronically controlled anti-patterning device

- Oil-free, easy maintenance construction

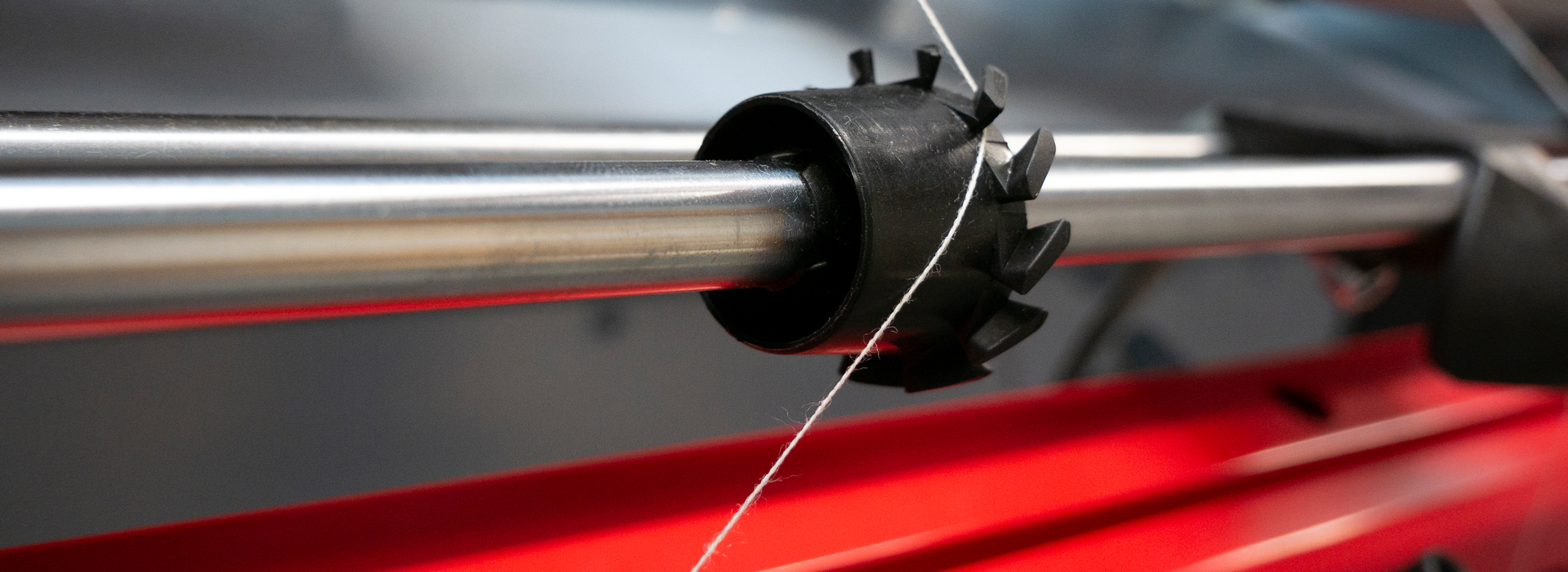

Very short conversion times by central adjustment of the yarn balloon guide and deflection roller

The yarn guide rollers used to influence the takeup tension can be centrally adjusted side by side to a uniform position.

The simple handling saves time, especially with frequent batch changes, and thus generates measurable added value.

The yarn balloon guide can also be centrally set to a uniform height. Discrepancies in the balloon yarn guide heights are thus avoided.

The quality of the cross-wound delivery package generated depends to a large extent on the takeup tension. This is the determining factor for package hardness.

By optimising the yarn balloon, energy can be saved with the central adjustment of the yarn balloon guide, depending on the material and yarn count.

Picture gallery

CompactTwister

Downloads

Find out more about our products. Here we provide you with all the relevant documents for download in PDF format.

CompactTwister product brochure EN

3.90 MB

CompactTwister product brochure DE

3.88 MB

CompactTwister product brochure ES

3.91 MB

CompactTwister product brochure RU

3.91 MB

CompactTwister product brochure TR

3.90 MB

CompactTwister product brochure ZH

4.05 MB

Strong and reliable life-cycle partnership.

Unique smart solutions to increase the benefit to the customer.

Notable performance and sustainability throughout the machine lifetime.

We keep you competitive.

Senses

With a single program, you can now manage your Saurer machines. Senses bundles and analyzes production, quality and performance data. Secure and from everywhere.