Corolab Q/XQ/XF service

Ensure long-term quality.

Saurer Corolab service: Ensure optimum quality levels at your spinning mill.

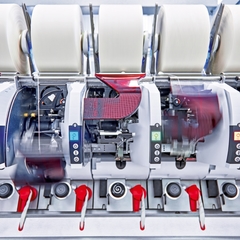

Properly functioning and optimally adjusted clearers prevent complaints about quality while ensuring maximum productivity.

We take care of this with our Corolab all-round service from calibration through to inspection and setting, up to the training of your employees. This way you are always on the safe side with continuous top yarn quality.

Saurer Corolab service: Ensure optimum quality levels at your spinning mill.

Properly functioning and optimally adjusted clearers prevent complaints about quality while ensuring maximum productivity.

We take care of this with our Corolab all-round service from calibration through to inspection and setting, up to the training of your employees. This way you are always on the safe side with continuous top yarn quality.

Your benefit

Guarantee your yarn quality

- Clean and maintain your Corolab sensors regularly for a trouble-free service life

- Avoid customer complaints about yarn

- Ensure professional handling by training your employees (optionally bookable)

Greater production reliability

- No unnecessary clearer cuts

- Less risk of unnecessary downtimes due to unscheduled maintenance work

- You can plan ahead for the maintenance of your Corolab system or the replacement of sensors

Reduce expenses for original parts

- Extend the service life of your Corolab sensors through careful cleaning and maintenance

- Sensors that are no longer working correctly are detected and, if technically feasible, corrected by adjusting internal parameters

- Alternatively, you will receive a cost-effective offer for replacing the sensors with completely overhauled sensors

Our offer

- Ensure top yarn quality and productivity with the Corolab all-round service

- Experienced employees from Customer Support inspect your Corolab systems and carefully check all functions and parameters using cutting-edge diagnostic technology

- Cleaning and calibration of all sensors

- Training (optionally bookable):

Basic course Corolab Q/XQ/XF, tailored to the design of your Corolab system

Documentation and certificate

- Test report with graphical representation of all technically and technologically relevant measured values

- Certificate of Corolab service in accordance with DIN EN ISO 9001

Certified measuring system

- We recommend calibration of your Corolab system at regular intervals to ensure that it continues to comply with the specifications of DIN EN ISO 9001

Application area

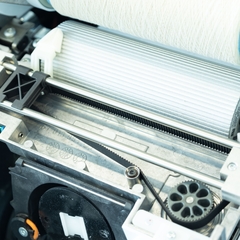

For all Autocoro and BD machines with Corolab

| Corolab XQ service | 139-400.516 |

| Corolab XF service | 139-400.517 |

| Corolab Q service | 139-400.518 |

| Please contact your Parts Manager or Service Manager, or email parts.spinning@saurer.com | |

| Please always state the machine number |

Downloads

Interested? Read our fact sheet for more information.

Corolab service fact sheet EN

59.73 KB

Corolab service fact sheet ES

62.81 KB

Contact us

Should you have questions about our products or require additional guidance, kindly get in touch with your local contact person. As your partner, we pride ourselves in providing expert and swift support