Autolab ET

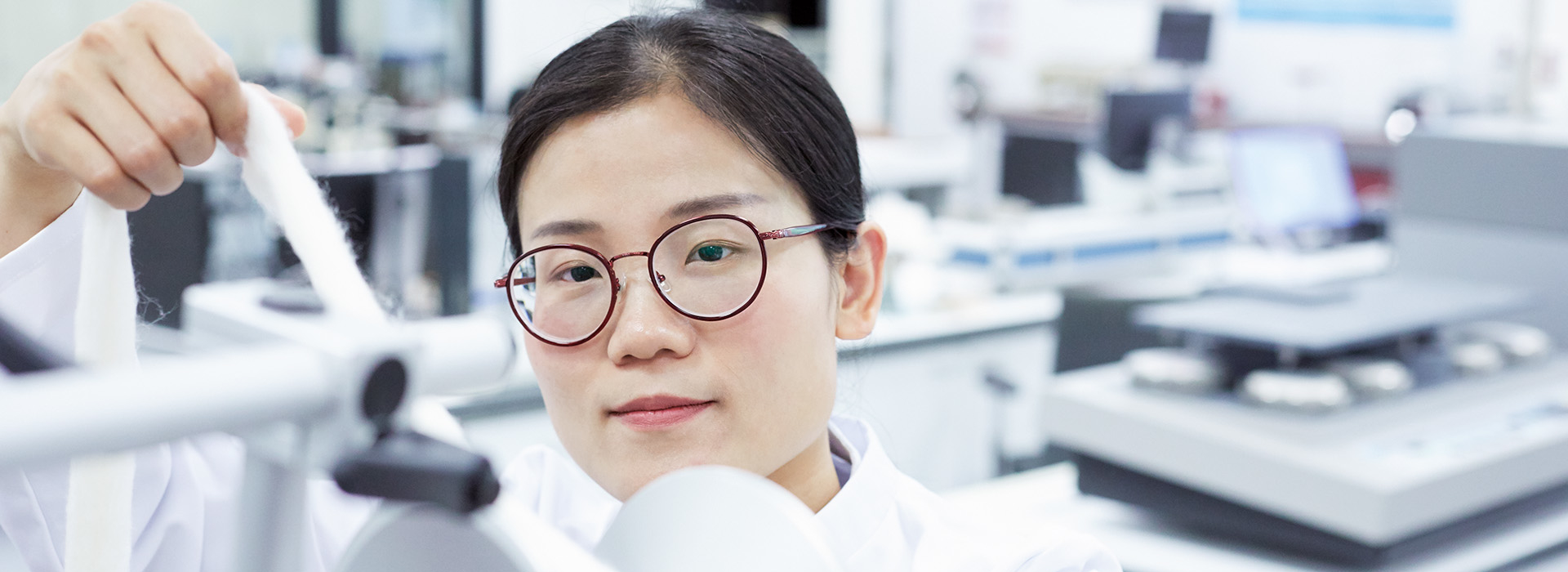

Determination of sliver evenness, yarn evenness, yarn hairiness.

Nowadays, a higher level of automation and a short reaction time to irregularities in the production process are key factors for a modern quality control system.

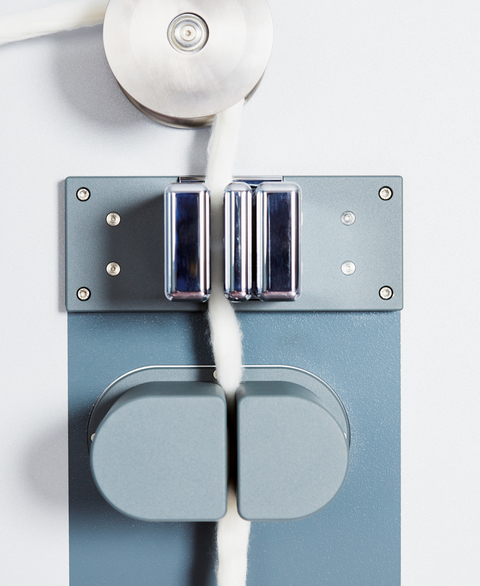

Measurable variables supplied by the system are the variation coefficient of the mass distribution along the yarn length, the spectrogram, and for staple fibre yarns, the number of neps, thick- and thin places (imperfections). Now all relevant parameters for sliver, rovings and yarns can be determined with one testing device and thus optimal running behaviour for the spinning machine can be ensured.

Nowadays, a higher level of automation and a short reaction time to irregularities in the production process are key factors for a modern quality control system.

Measurable variables supplied by the system are the variation coefficient of the mass distribution along the yarn length, the spectrogram, and for staple fibre yarns, the number of neps, thick- and thin places (imperfections). Now all relevant parameters for sliver, rovings and yarns can be determined with one testing device and thus optimal running behaviour for the spinning machine can be ensured.

Test basics

- Yarn evenness is tested across a wide yarn fineness range in accordance with ISO 16549.

- A modern, integrated laser sensor generate the basis of the automatic measurement of yarn hairiness.

- Determination of the total yarn hairiness and the hair length classification is made on this basis.

Picture gallery

Related articles

Here you will find further information – for example application reports, customer success stories and interviews – about the above product.

Downloads

Find out more about our products. Here we provide you with all the relevant documents for download in PDF format.

Autolab Brochure EN

950.77 KB

Autolab Brochure DE

946.76 KB

Autolab Brochure CN

630.62 KB

Autolab Brochure TR

947.64 KB

Autolab Brochure ES

946.36 KB

Autolab Brochure PT

953.42 KB

Senses

With a single program, you can now manage your Saurer machines. Senses bundles and analyzes production, quality and performance data. Secure and from everywhere.

Strong and reliable life-cycle partnership.

Unique smart solutions to increase the benefit to the customer.

Notable performance and sustainability throughout the machine lifetime.

We keep you competitive.

Contact us

Should you have questions about our products or require additional guidance, kindly get in touch with your local contact person. As your partner, we pride ourselves in providing expert and swift support.