Visitors to Exintex can expect to see a machine portfolio perfectly suited to the needs of the Central and South American textile market. It includes a wide range of spinning machines, from preparation and roving to flexible solutions in ring, rotor and air spinning. Saurer's experts will be happy to welcome you and to discuss the latest innovations of the all-new product portfolio. All Saurer spinning and twisting machines guarantee the highest productivity with reduced manpower thanks to the automation features already integrated in the machine. In addition, Saurer offers a wide range of automation equipment for roving, ring spinning, compact spinning, rotor spinning, air spinning and twisting, depending on the customer's needs.

The fully automated rotor spinning machine Autocoro 11 has been upgraded to process even the shortest fibres with the Autocoro 11 in the Recycling Xtreme version. The Autocoro 11 also offers additional 10% energy savings compared to Autocoro 10 and more powerful automation. Klaus Boltz, General Manager of Saurer Mexico, explains: "With the Autocoro 11 recycling Xtreme, we offer a solution which is optimised for extremely short mechanically recycled fibres and customers can explore the limits of their recycled raw material with our machines, while still being highly productive. For decades, all Saurer machine developments have been focused on energy saving to save resources and energy costs".

Saurer's Autoairo air spinning machine sets new standards in productivity, automation and efficiency for economic air spinning and is now processing cotton and cotton blends. "With the new Autoairo air spinning technology, Saurer can produce Belairo yarns, which are a cost-efficient alternative to combed ring spun yarns. Low hairiness, low pilling and the conical package format make the Belairo yarns ideal for use in the knitting industry. Autoairo can process not only viscose fibres, but also cotton and cotton blends. Discover Saurer's air spinning technology on the Autoairo model running on the booth," adds Klaus Boltz.

The Saurer ring-spinning portfolio offers a flexible range of ring-spinning and compact-spinning machines for all spinning mill requirements. Equipped with energy saving solutions and the well-known Texparts quality components, the Saurer ring-spinning portfolio offers the right solution for every application and delivers excellent yarn quality, and several options are available for the use of recycled fibres in roving and compact-spinning.

In the area of pre-spinning, Saurer introduced the new Autocard SC7 at ITMA Asia in November 2023. With its focus on automation, digitalisation, and ergonomics, the new Autocard enables spinning mills to achieve more production and higher sliver quality with less manpower.

The semi-automatic rotor spinning machines, the BD 8 and the BD 480 are now offering a doffer as an option for increased automation, improving workplace ergonomics.

With the Texparts product line Saurer offers high quality components for the textile industry including drafting systems and spindles, spinning rings and travellers, as well as bearings for ring-spinning and rotor-spinning, winders, and twisters. The Texparts components ensure excellent yarn quality, maximum productivity and with some products also energy savings.

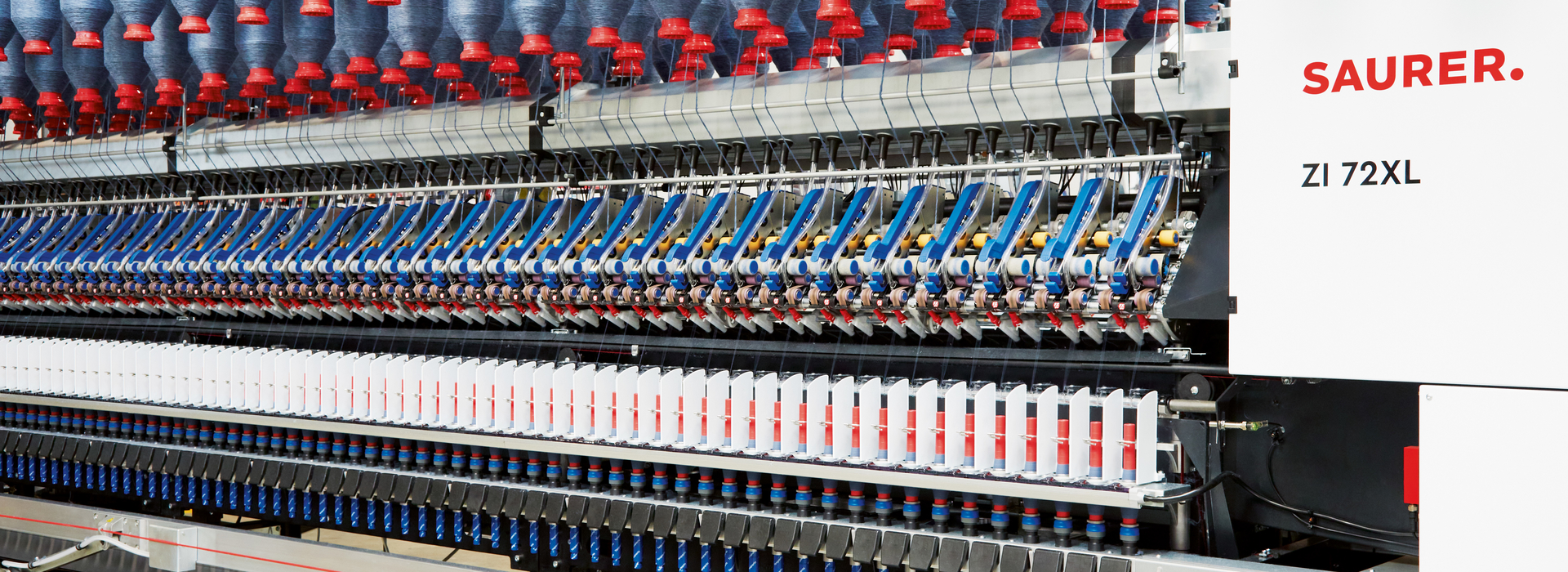

Saurer experts will explain the latest developments in twisting and cabling technology. The CompactTwister offers new standards in twisted yarn quality, flexibility, energy consumption, robustness, reduced space requirements and ease of maintenance. Twisting of recycled yarns is a smart way to increase the yarn tenacity. The CarpetTwister 1.12 / CarpetCabler 1.12 is equipped with an enhanced servo drive technology and data management to reliably and confidently meet the challenging demands of a rapidly changing market. The TechnoCorder TC2 now offers these new features and options: PreciWinding (TC2 Plus), oiling device, balloon limiter ring and QualityGuard.

Sustainability also implies longer product life. SUN-Service Unlimited offers solutions for a long and sustainable life of Saurer spinning machines as well as upgrade kits for processing recycled fibres. Additionally, Saurer provides solutions to improve the energy efficiency of your current machinery, because every watt we can save counts for our planet.