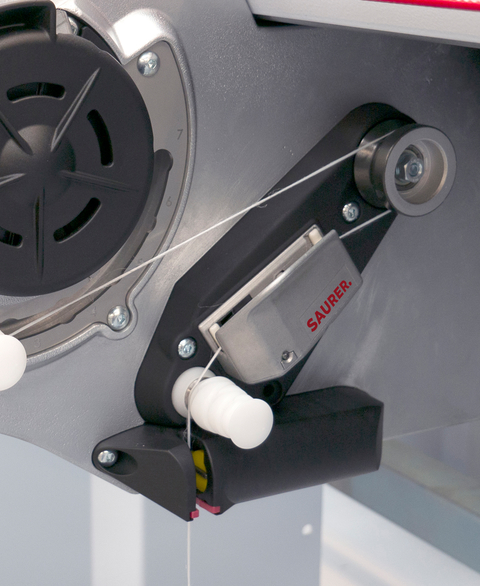

As a leading company on the market, we offer innovative solutions for monitoring and ensuring yarn quality with our CarpetCabler. Due to high rotation speeds during the cabling process, two decisive aspects of yarn quality become important: the yarn tensions and the uniformity of the spindle speed. Our CarpetCabler covers the entire spectrum of BCF yarns. From a tried-and-tested mechanical drive to an electronic motorised spindle with speed monitoring, the CarpetCabler generates uniform twists in the yarn. A range of pneumatic sensing elements and electronic sensors are available to generate and control the necessary yarn tension.

The effectiveness of these innovative quality-assurance solutions has been proven many times over in practice and makes a significant contribution to ensuring yarn quality in the processing of BCF yarns. Our customers appreciate not only the quality of our products, but also the efficiency and reliability of our technologies.