Drafting systems for worsted ring spinning

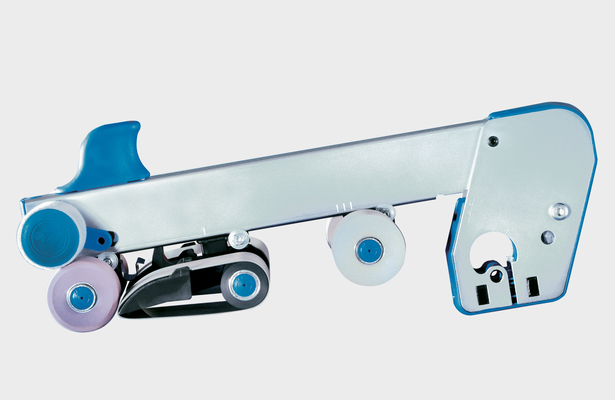

PK 1660 weighting arms

The solution for worsted yarn ring spinning

Texparts PK 1600 series arms have long been the industry standard for worsted yarn spinning. In the development of PK 1660 focus was set on increasing customer benefits in both handling and lifetime. This ensures improved process reliability which results in optimum quality yarn.

PK 1660 weighting arms are mainly intended for 3-roller double-apron drafting systems on worsted ring spinning machines. They are suitable for spinning wool or man-made fibers or blends of both types up to approx. 200 mm length.

Available gauges: 75 / 82,5 / 90 /100 mm

Advantages

- Optimized surface protection

- Smaller load tolerances

- Visible load indicators

- Ergonomic handle

- Easy disassembling of top rollers

| Rear and front top rollers without cots* | ||

| Ref. nos. | Gauge (mm) | Outer ring width (mm) |

| LP 1014-1253 740 | 75.0 | 34.0 |

| LP 1014-1253 741 | 82.5 | 34.0 |

| LP 1014-1253 742 | 90.0 | 34.0 |

| Apron top rollers without cots* | ||

| LP 1016-1256 711 | 75.0 | 34.0 |

| LP 1017-1256 712 | 82.5 | 40.0 |

| Top apron cradle | ||

| Ref. nos. | Gauge (mm) | Top rollers |

| OH 2402-1253 436 | 75.0 | LP 1016 |

| OH 2402-1253 437 | 82.5 | LP 1017 |

* Cot quality to be decided by customer

PK 6000 weighting arms

Excellent quality for long-staple ringspinning machines.

The Weighting arm PK 6000 is with individual pneumatic loading of the top rollers. It is simple to assemble.

Its fasteners are easily accessible. The height can be adjusted and controlled easily and quickly with simple gauges. The draft field setting is referred to the front bottom roller. That gives more time for other jobs.

Available gauges: 75 / 82,5 mm

Application

The fully pneumatic weighting arm with three-roller double-apron drafting systems on worsted ring spinning machines is suitable for spinning wool, man-made fibres or blends of both types up to 200 mm fibre length.

Advantages

- Excellent spinning results

- Constant weighting load from spindle to spindle

- Centralized and infinite setting pressures

- Centralized setting of partial load

- Easy setting

- Easy handling

- Top apron cradle concept with individual tensioning system

Technical information

A comprehensive safety concept based on three steps:

A pressure monitor ensures that the ring spinning machine is secured against dropping out of air pressure below the limit of 3 bar.

| Rear and front top rollers without cots* | ||

| Ref. nos. | Gauge (mm) | Outer ring width (mm) |

| LP 1014-1253 740 | 75.0 | 34.0 |

| LP 1014-1253 741 | 82.5 | 34.0 |

| Apron top rollers without cots* | ||

| LP 1014-1253 740 | 75.0 | 34.0 |

| LP 1015-1253 744 | 82.5 | 40.0 |

| Top apron cradle | ||

| Ref. nos. | Gauge (mm) | Top rollers |

| OH 6022-1254 311 | 75.0 | LP 1014 |

| OH 6022-1254 312 | 82.5 | LP 1015 |

* Cot quality to be decided by customer

Downloads

Find out more about our products. Here we provide you with all the relevant documents for download in PDF format.