FusionTwister

倍捻机

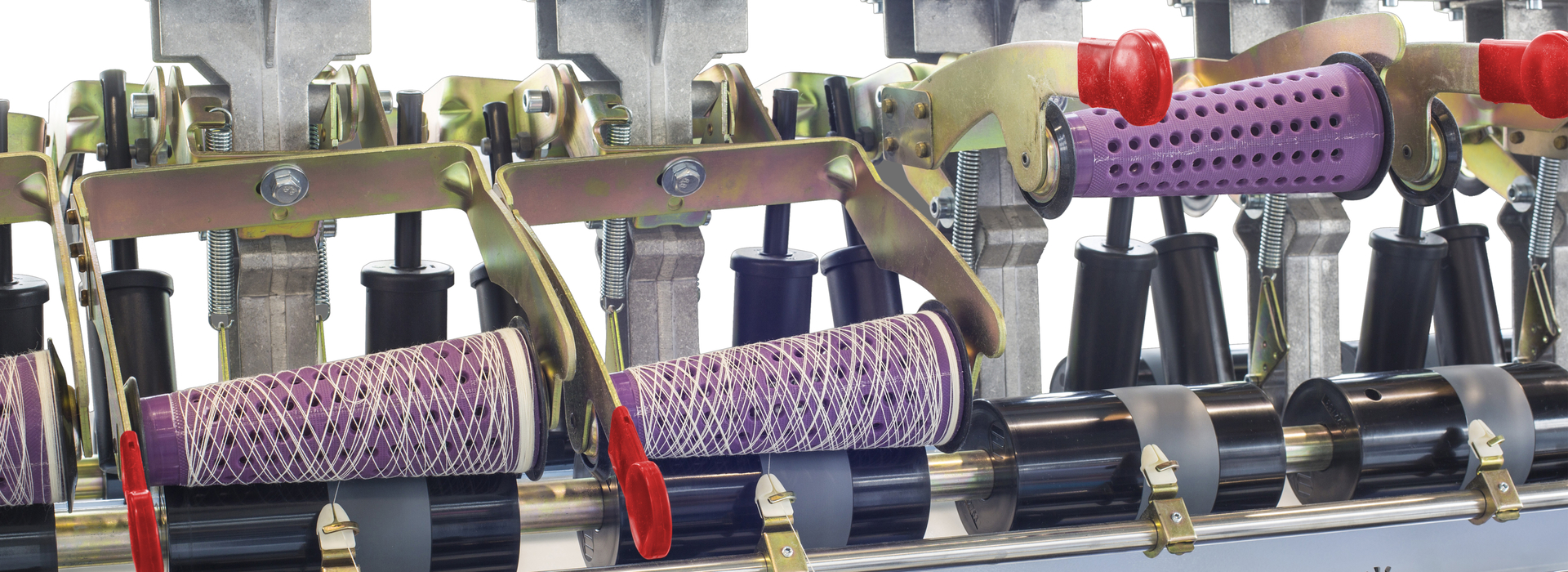

我们以满足客户需求为己任,基于深入的市场调查开发的富俊倍捻机,在倍捻机质量和性能方面设置新标准,是满足当前市场需求的必然选择。

我们以满足客户需求为己任,基于深入的市场调查开发的富俊倍捻机,在倍捻机质量和性能方面设置新标准,是满足当前市场需求的必然选择。

亮点

- 最佳品质的交叉卷绕筒子

- 减少能耗

- 高效生产

- 空间需求小

- 灵活性和可靠性更高

- 噪音等级更低

- 操作和安装时间短

- 简易调节

- 维护需求小

- 性价比最佳

更多创新...

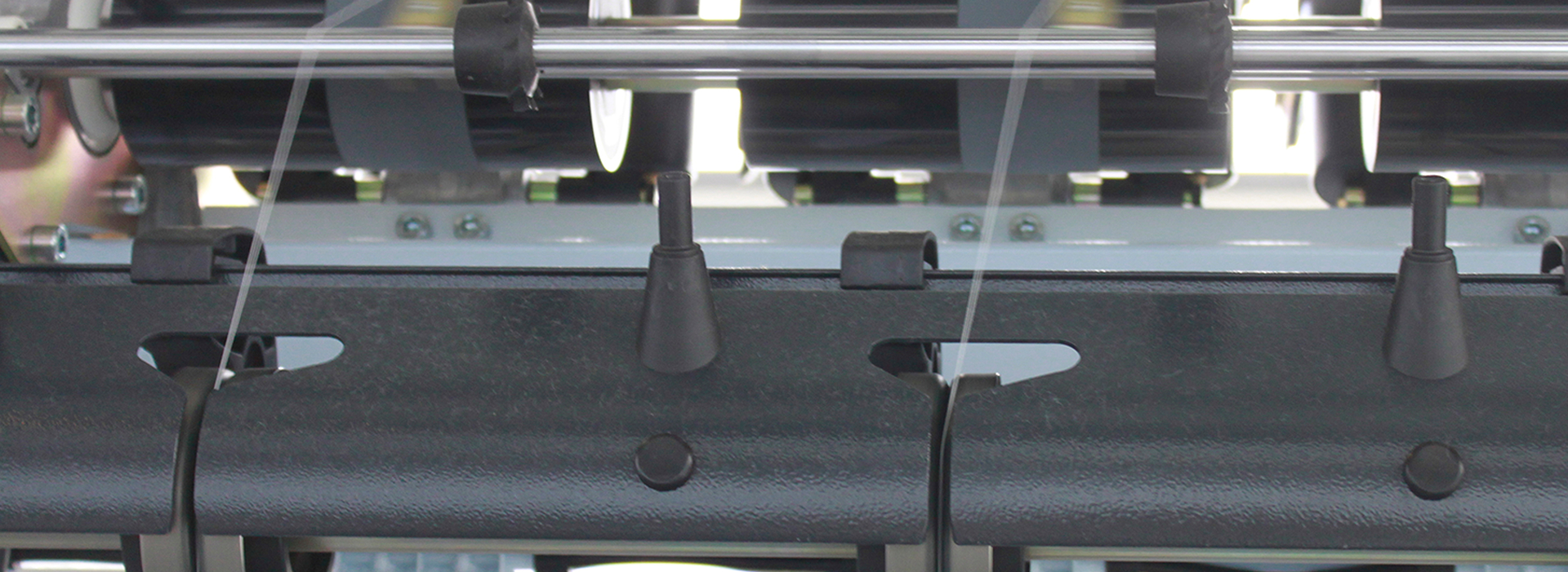

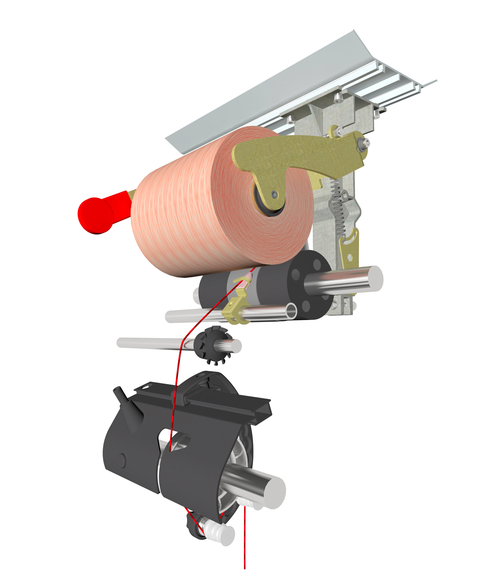

HD-锭子

HD-锭子形成了一个高效的气圈几何区,比起传统锭子,可实现大幅节能。HD-锭子可在VTS-08和VTS-10机型上使用。

多种喂入尺寸

富俊倍捻机单个筒子喂入有三种喂入尺寸6",7"和8"。

图片库

FusionTwister

相关阅读

您将找到更多上述产品的相关信息,例如:应用报告、客户成功案例和访谈。

您还可能感兴趣

Sun – 服务无限

整个生命周期内强大可靠的伙伴关系。

深具特色的智能解决方案,让客户获享更大利益。

在设备整个生命周期均实现卓越性能和可持续性。

卓郎为您铸就强大竞争实力。

咨询

安装

Academy 学院

原装备件

保养和维修

升级和改造

Secos – Saurer 客户门户