CarpetCabler 1.10

直捻机

35年来,卓郎地毯纱直捻机和地毯纱倍捻机持续为客户生产精密地毯和其他纺织品提供优质地毯纱。

随时为客户提供创新性的开发和最新技术,与客户携手共迈新征程,是卓郎几十年来始终如一的发展方针。

卓郎新系列地毯纱直捻机/倍捻机1.10,为客户掌控不断变化的市场需求创造最大可能。

35年来,卓郎地毯纱直捻机和地毯纱倍捻机持续为客户生产精密地毯和其他纺织品提供优质地毯纱。

随时为客户提供创新性的开发和最新技术,与客户携手共迈新征程,是卓郎几十年来始终如一的发展方针。

卓郎新系列地毯纱直捻机/倍捻机1.10,为客户掌控不断变化的市场需求创造最大可能。

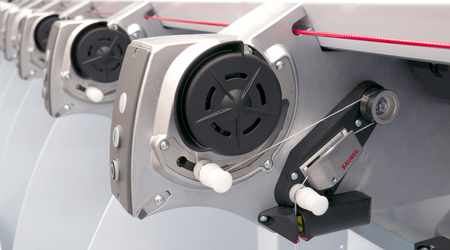

最佳节能锭子家族

锭子家族包括以下型号:

| 尺寸[毫米] | 通用型锭子285 | 锭子285 | 锭子260 |

| 锭罐喂入卷装 | 285 | 285 | 260 |

| 锭距 | 495 | 495 | 445 |

优化的部件实现了机器高效节能

- 高效的主驱动马达

- 优化的整个锭区轴承

- 上行式加捻时输出速度高达120 m/min,生产效率更高

- 锭距缩小,所需空间更小

- 气圈张力降低,生产速度更高

中央调节,减少机器操作时间

快速、简单、精确的马达驱动系统,优化操作高度.

经过优化的所有气圈导纱钩高度一致.

卷装输送带可快速搬运成品卷装纱

Volco-/Creeljet气动穿纱系统实现快速方便穿纱

电脑控制的伺服 - 机械式齿轮箱

为什么要在福克曼直捻机上加捻地毯纱?

- 直捻是地毯生产前对纱线的机械升级工艺。

- 在垫毯和地毯的生产过程中,直捻的纱线是确保形成高质量绒头的理想材料。

- 在直捻工序中,两股单纱合股并捻在一起,单纱不带任何捻度。

直捻到倍捻的转换

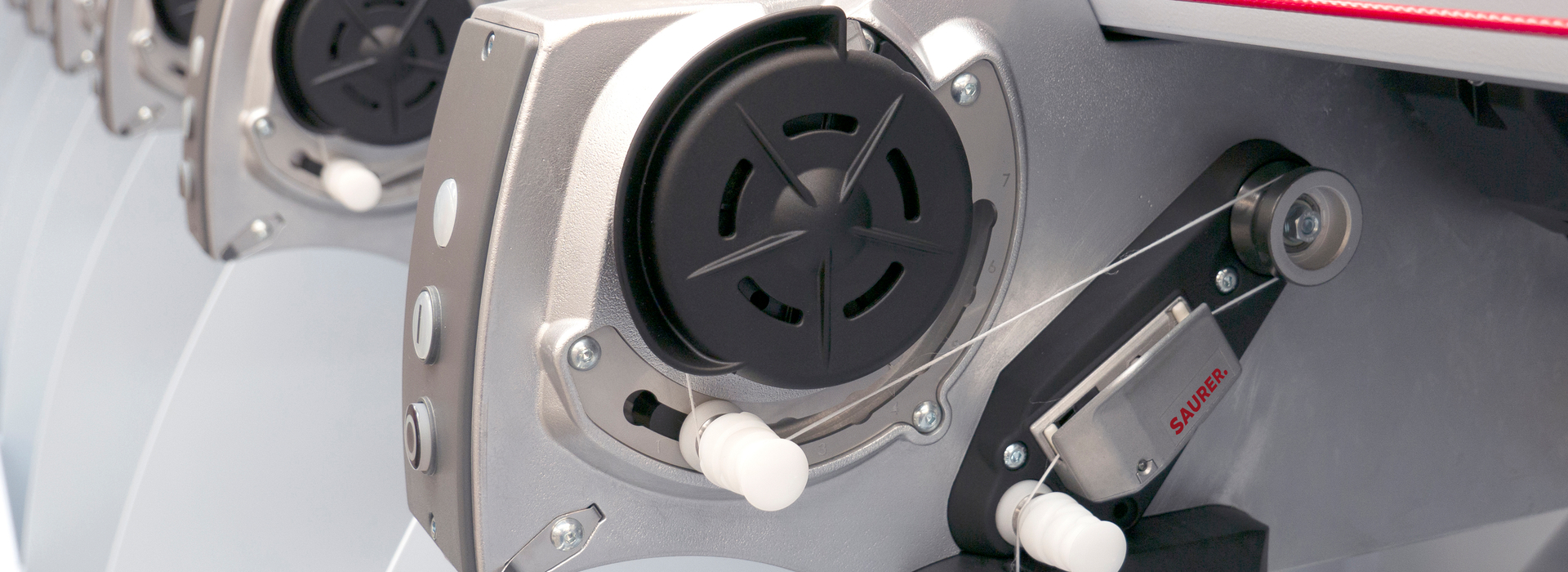

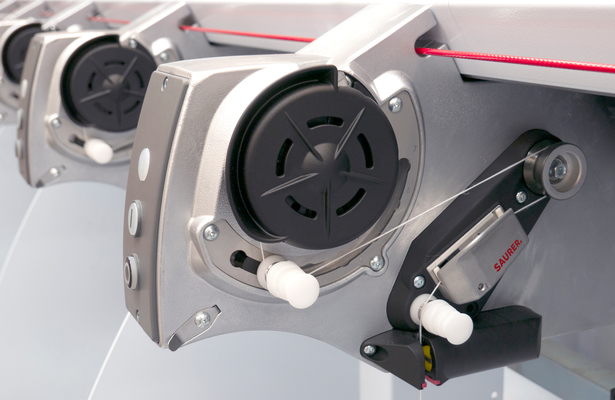

通用型空心轴锭子可轻松实现倍捻和直捻转换。优质耐磨的纱线通道表面,确保导纱轻柔无损。理想设计的锭罐,可容纳最大量的喂入卷装。储纱盘耐磨的特殊表面,保证了纱线气圈内张力水平的平衡。

创新

- 控制面板(人机界面)

新型操控面板,配备多点触控技术和创新的用户界面,让操作更加直观、便捷。

操作面板可以记录、控制和监测整个生产工序,管理机器、纱线批次参数和生产数据。

简单易懂的用户界面可以快速、直接地输入参数,简化机器控制,轻松调用存储的批次参数,使操作更简便。

- 超喂罗拉

根据卷绕角度,预卷取罗拉可以将气圈张力值降低到理想的卷取张力。超喂盖板保证了操作安全性,还可以抬升纱线夹持元件和储纱销,方便退绕辅助装置临时存储。

更多创新…

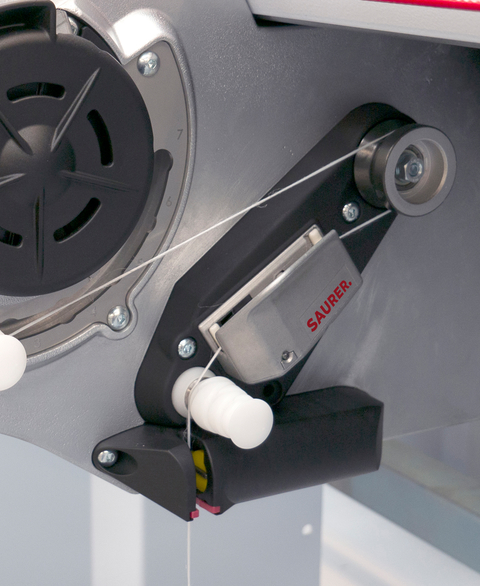

质量传感器

我们最新一代质量传感器可以将纱线测试提升到一个新高度。结合智能软件和创新的评估技术,新型质量传感器可为客户提供最佳纱线质量。

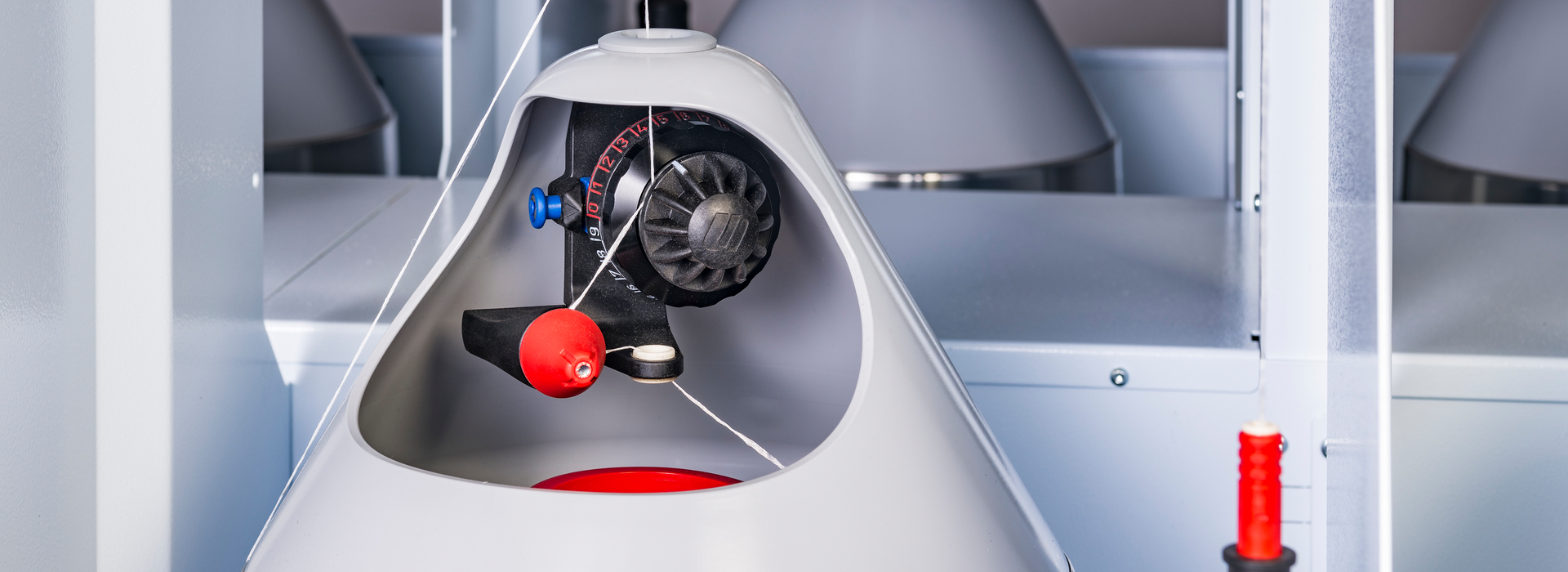

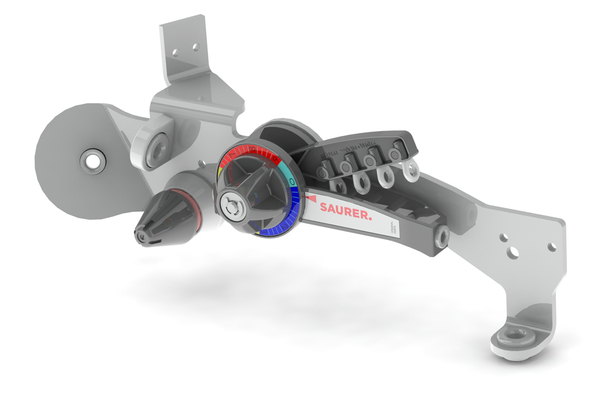

气动式升降式纱架

气动式升降式纱架操作简单明了,筒子装卸更便利。操作高度降低,让操作人员上纱更容易。气动式升降式纱架还可以自动地移动到操作位置。

更多优势:

- 人性化设计的上纱位置

- 筒子升-降装卸操作简单

- 稳定而可靠

- 自动锁定

- 优化的纱线通道

- 可灵活地装载高达3个筒子,总重最大达16kg

- 可另外配插栓,满足所有用户的需求

- 多种纱线张力器

- 操作简单

图片库

CarpetCabler 1.10

相关阅读

您将找到更多上述产品的相关信息,例如:应用报告、客户成功案例和访谈。

整个生命周期内强大可靠的伙伴关系。

深具特色的智能解决方案,让客户获享更大利益。

在设备整个生命周期均实现卓越性能和可持续性。

卓郎为您铸就强大竞争实力。