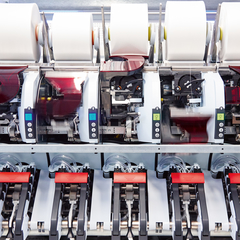

JSC 230 Card

The best combination of yield and quality.

Card JSC 230 integrates the innovative highlights of the intelligent Autocard. It can fully meet the spinning requirements of flexible configuration of differentiated fibers, and achieve maximum output in a smarter and more economical way.

The right combination of blow room and carding technology ensures excellent fiber utilisation and sliver quality for high efficiency and yarn quality in spinning.

Card JSC 230 integrates the innovative highlights of the intelligent Autocard. It can fully meet the spinning requirements of flexible configuration of differentiated fibers, and achieve maximum output in a smarter and more economical way.

The right combination of blow room and carding technology ensures excellent fiber utilisation and sliver quality for high efficiency and yarn quality in spinning.

- Up to 20% more productivity

- Up to 2.82m² carding area

- Space saving and lower energy cost

- Lower maintenance cost in production

- Reduced workload

Highlights

- Single or triple licker-in for flexible process

- Prime components for lower energy consumption

- Optimised airflow for higher efficiency waste suction

- Long-term and short-term autolevelling for an excellent sliver quality

- Seamless can change for higher quality and higher production

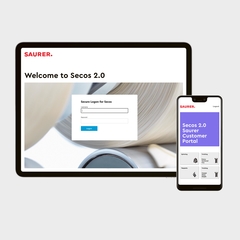

- Mill management system Senses for analysing all spinning data in one program - in real time, securely and from anywhere

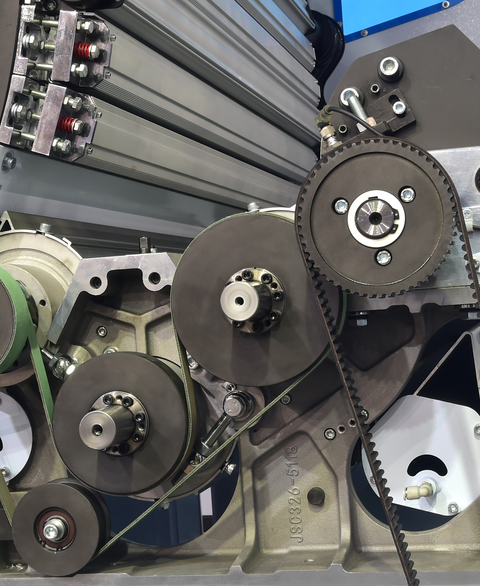

JSC 230 - Triple licker-in

The impurity ratio of sliver is high when the raw material is machine-harvested cotton. JSC 230A is configured with V-sharp triple licker-in, and use the forward feeding structure can reduce the impurity ratio in sliver effectively. The test result shows the ratio can decrease 15% when use triple licker-in module.

Downloads

Find out more about our products. Here we provide you with all the relevant documents for download in PDF format.

JSC 230 product brochure EN

1.69 MB

JSC 230产品手册 中文版

1.82 MB

Senses

Sie können Ihre Saurer-Maschinen jetzt mit einem einzigen Programm verwalten. Senses bündelt und analysiert Produktions-, Qualitäts- und Leistungsdaten. Sicher und von überall.

Starke, zuverlässige Life-Cycle-Partnerschaft.

Einzigartige intelligente Lösungen zur Erhöhung des Kundennutzens.

Bemerkenswerte Leistung und Nachhaltigkeit auf Maschinenlebenszeit.

We keep you competitive.

Contact us

Should you have questions about our products or require additional guidance, kindly get in touch with your local contact person. As your partner, we pride ourselves in providing expert and swift support.