Visitors to the CAITME can expect to see a machine portfolio that is ideally suited to the needs of the Central Asian textile market. The Saurer experts look forward to meeting customers and informing them about innovative solutions for spinning and twisting that also focus on productivity, energy saving, digitalisation and automation. Saurer also offers retrofit and upgrade solutions to save energy and labour.

Spinning solutions

Saurer offers a wide range of spinning machines, from preparation machines and roving frames to flexible solutions in air, ring and rotor spinning and automation systems.

At CAITME, Saurer will present the Autocard, which enables spinning mills to achieve more production and higher sliver quality with less manpower. The card offers a 20% increase in productivity and delivers the same quality thanks to the larger carding area. The Saurer card portfolio offers excellent solutions for all kinds of fibres.

Saurer's Autoairo air-spinning machine spins at the highest speeds and is extremely efficient thanks to the high level of automation. Discover Saurer's air-spinning technology on the Autoairo model running with local cotton on the booth.

On the 12th of September, Saurer will be holding a seminar on “Spinning Cotton on Autoairo” in the congress hall at the Expo Center from 15-16 h!

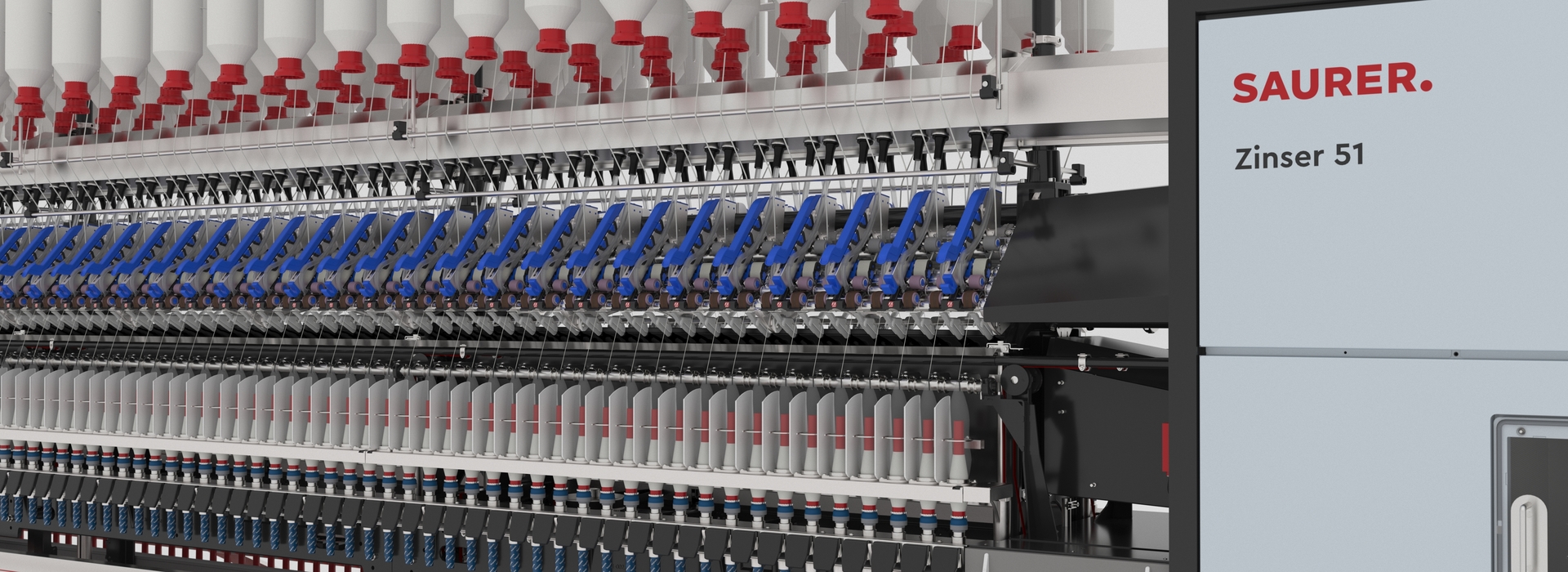

Uzbekistan is a ring-spinning dominated market and hence Saurer is pleased to introduce the Zinser 51 ring spinning machine, running on the booth. The robust Zinser 51 has been developed with a focus on increasing efficiency, energy saving and production flexibility. The full range of flexible electronic drafting for easy adjustment and the maintenance free middle drive, even for superlong spinning machines are just two of the many highlights.

With the Texparts Eshape spindle and Spinnfinity, the Zinser 51 can achieve top speeds of up to 30,000 rpm and the Impact FX Pro enables the production of high quality compact yarns or the processing of recycled fibres. The Saurer experts on the booth will explain in detail the benefits for each specific application.

The fully automated rotor spinning machine Autocoro 11 enables mills to reach the highest rotor-spinning productivity on the market. The technology leader in the market has now been upgraded to process even the shortest fibres. The Autocoro 11 offers about 10% energy savings compared to the Autocoro 10 and more automation features. The Autocoro 11 - with the “Recycling Xtreme” options - enables spinning extremely short mechanically recycled fibres at highest take-off speeds.

The semi-automatic rotor spinning machine BD 8 offers an economical high-quality and energy-saving solution for processing virgin as well as recycled fibres, blends or waste. The BD 8 can now be equipped with up to four automatic doffer units (DU), which change the packages without interrupting the spinning process, increasing the productivity. The Digital Joint Spinning In technology automatically starts all 600 spinning positions after a power failure - within 10 minutes the whole machine is running again.

With the Texparts product line, Saurer offers high-quality components for the textile industry, including drafting systems and spindles, spinning rings and travellers, as well as bearings. Texparts components ensure excellent yarn quality and maximum performance. The high-speed spindle Eshape - combined with the Spinnfinity zero underwinding system - enables remarkable energy savings of up to 6%.

Sun - Service Unlimited offers solutions for a long and sustainable life for installed Saurer machines. Customers can equip the existing machines with the latest upgrades to maximise the productivity or add new features for recycled fibre processing. The updates and upgrades, smart preventive maintenance services or technology kits will keep the mill’s production on a competitive leben throughout the whole lifetime of the machines. There are many solutions available to improve the quality, performance and profitability of spinning mills.

Twisting solutions

The CompactTwister features an advanced spindle and drive design that ensures low power consumption and fast doffing times while maintaining a low yarn breakage rate. With balloon limiters, energy-saving spindles, optimised drives and numerous other innovations integrated into Saurer's twisting and cabling machines, customers can achieve significant energy savings - more than ever before. Twisting recycled yarns with the CompactTwister increases strength for downstream processing and expands the range of applications for the yarn.

The CarpetCabler/CarpetTwister 1.12 features, among many other improvements, an energy efficient spindle range and central computer-controlled balloon adjustment. This new range enables customers to meet the evolving demands of today's market with both reliability and precision.