Intelligent laboratory systems thanks to cooperation

Optimal use of raw materials, continuous quality assurance in production: the new Autolab laboratory systems deliver exact metrics to ensure this happens.

Optimal use of raw materials, continuous quality assurance in production: the new Autolab laboratory systems deliver exact metrics to ensure this happens.

From raw material to finished yarn, always know exactly which quality is being produced so that processes and machines can be optimised: that's how you achieve significant increases in efficiency in staple-fibre spinning. One prerequisite for this is that it must be possible for fibres and yarns to be precisely tested during all process stages. Another is that this data must be available to individual specialised areas within textile process chains at all times. With the new Autolab laboratory systems, Saurer offers a solution unique to the market: easily operated measuring and testing devices that deliver practice-oriented, absolute measured values that can be seamlessly integrated with data from production. Because Saurer is working with the company Textechno in the area of staple-fibre spinning, their many years of expertise made their mark on the Autolab laboratory systems.

The product line includes all necessary measuring and testing devices for comprehensive quality control from textile raw material to yarn. Every individual component contributes small but crucial advantages for efficiency. As an example, one of the measuring devices for fibres is Autolab LT. It measures fibre length distribution and tests fibre strength – one after the other automatically on the same sample. The result is represented in absolute measured values or directly in physical base units. This means that Autolab LT does not require calibration cotton.

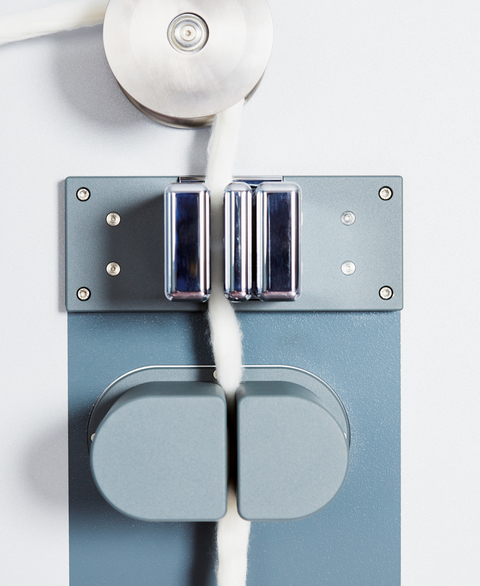

In the yarn area, information on the uniformity of the sliver and the yarn, imperfection and hairiness, amongst others, is needed. Using Autolab ET means all relevant parameters for slivers, rovings and yarns can be determined with one testing device and thus ensuring optimal running behaviour for the spinning machine.

Tests are the most useful when tested values are available at the right place and the right time in the production process. Only Saurer provides seamless integration. If the offline data of the Autolab testing systems is combined with the online data of the machines, all the necessary information for optimal production of the required product properties is always available. Intelligent digitalisation thus becomes the key to greater raw material efficiency and improved product quality. Moreover, traceability and reproducibility are ensured thanks to centralised data storage.

This article, which appeared in the 01 2020 edition of our "Insight" customer magazine, is available in four languages. Here you can also access the entire magazine.