Doffing unit for your BD 8, 7

Increase your flexibility and productivity

Take a step towards automation with our new Doffing unit (DU) for BD 8 and BD 7.

Save operator workload and react flexible on market demands with our automated package change system while keeping a constant package length.

Take a step towards automation with our new Doffing unit (DU) for BD 8 and BD 7.

Save operator workload and react flexible on market demands with our automated package change system while keeping a constant package length.

Explore the BD 8

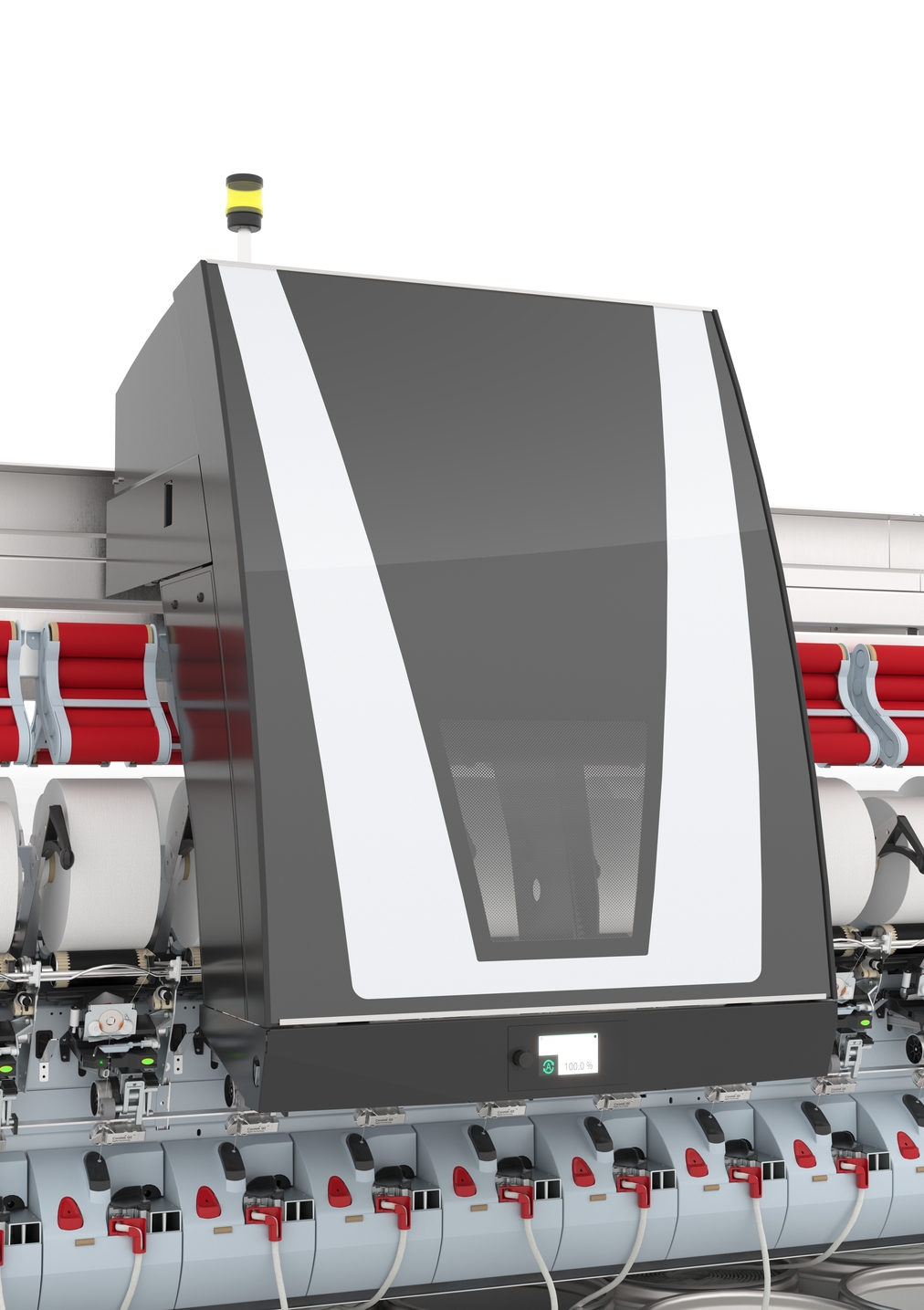

New automatic doffing unit (DU)

Our offer

- Upgrade your BD 8, 7 machine with our new Doffing unit (DU)

Your benefit

Increased efficiency

- Gain maximum doffing efficiency with a package change in 10 seconds and a travelling speed of 24 metres per minute

- Gentle and controlled package handling through automated doffing process

- Continuous cleaning of the spinning units through the integrated travelling blower

- Fast and easy installation: The DU comes fully assembled and only needs to be plugged in by technician

Save operator workload

- Increase of profitability due to reduction of operator workload

- Operator can use saved workload for more valueable tasks, e.g. piecing

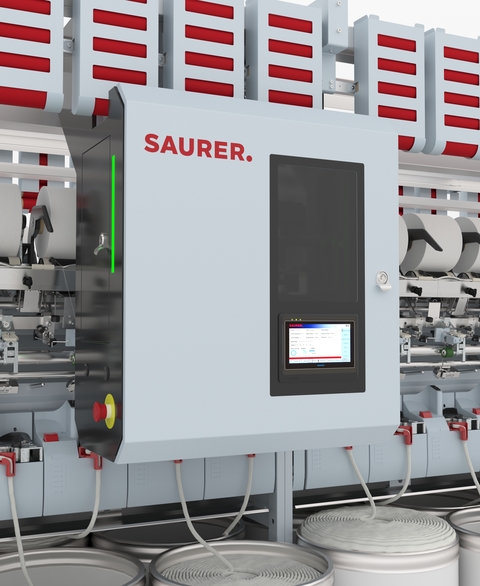

Doffing unit upgrade for your BD 480 Plus and BD 480

Enhance your operations with our new Doffing unit for BD 480 Plus and BD 480, paving the way for automation.

Save operator workload and react flexible on market demands with our automated package change system while keeping a constant package length.

Upgrade your BD 480 Plus with our new Doffing unit

Our offer

- Upgrade your BD 480 Plus and BD 480 machine with our new Doffing unit (DU)

Your benefit

Increased efficiency

- Gain maximum doffing efficiency with a package change in 13 seconds and a travelling speed of up to 23 m/min

- Gentle and controlled package handling through automated doffing process

- Fast and easy installation: The DU comes fully assembled and only needs to be plugged in by technician

Save operator workload

- Increase of profitability due to reduction of operator workload

- Operator can use saved workload for more valueable tasks, e.g. piecing

Application area

For all BD 8, 7, BD 480 Plus, BD 480 machines

| BD 8, 7 | 168-400.035 |

| BD 480 Plus, BD 480 | 700-400.058 |

| Please contact your Parts Manager, Service Manager, or email parts.spinning@saurer.com | |

| Please always state the machine number |

Downloads

Interested? Read our fact sheet for more information.