CarpetTwister

二合一倍捻机

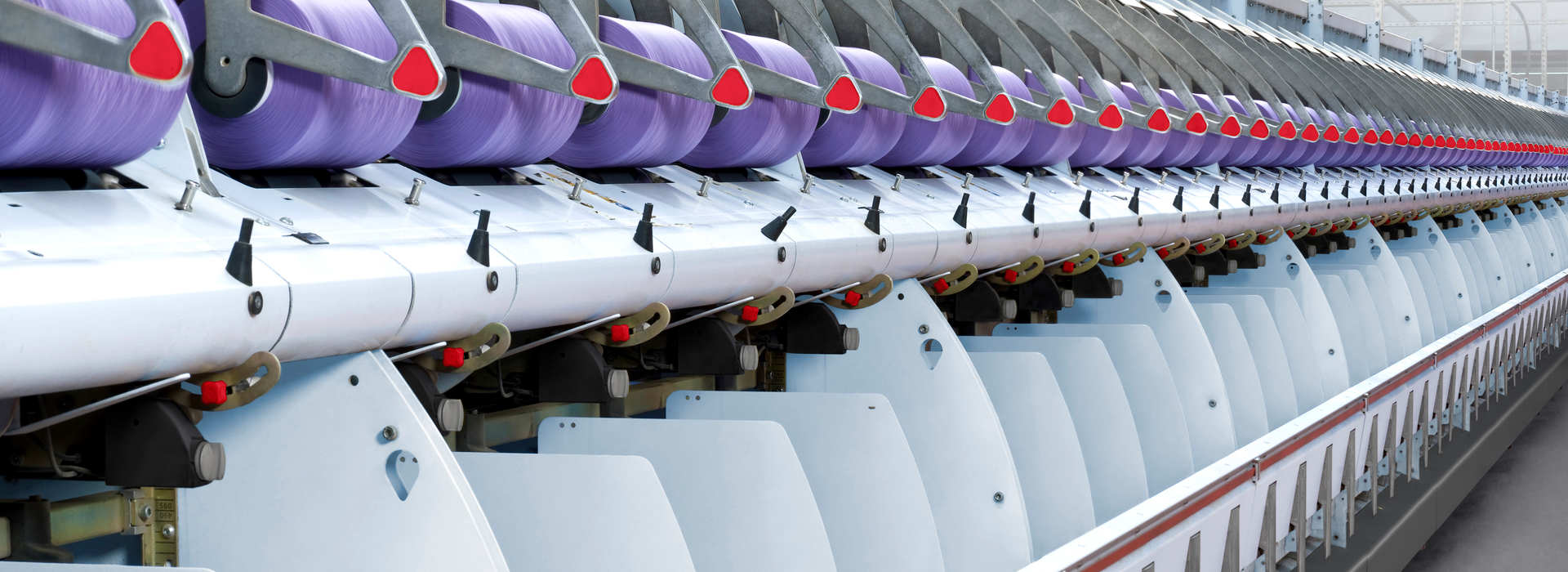

数十年来,卓郎地毯纱直捻机和地毯纱倍捻机一直以最经济的方式,成功地为客户生产高档地毯纱和其他纺织品提供优质地毯纱。

从而为客户掌控不断变化的市场需求创造最大可能。

数十年来,卓郎地毯纱直捻机和地毯纱倍捻机一直以最经济的方式,成功地为客户生产高档地毯纱和其他纺织品提供优质地毯纱。

从而为客户掌控不断变化的市场需求创造最大可能。

能耗更低

节能

能耗更低

最佳节能锭子家族

锭子家族包括以下型号:

|

尺寸[毫米] |

通用型锭子285 |

锭子285 |

锭子260 |

锭子220 |

|---|---|---|---|---|

|

锭罐喂入卷装 |

285 |

285 |

260 |

220 |

|

锭距 |

495 |

495 |

445 |

445 |

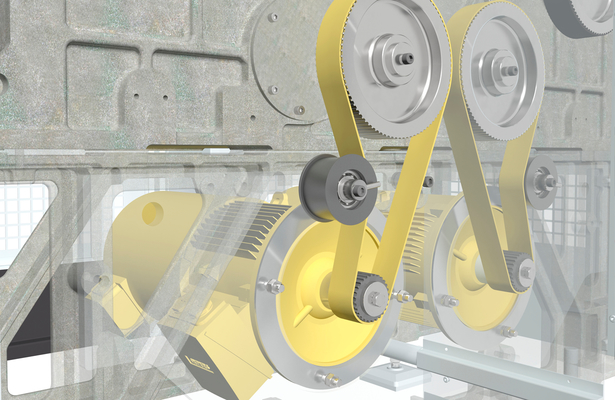

能源优化的部件实现了机器的高效节能

-

高效的主驱动马达

-

优化的整个锭区轴承

更高的生产效率与卷装密度

经济

更高的生产效率与卷装密度

- 上行式加捻时输出速度高达120 m/min,生产效率更高

- 锭距缩小,所需空间更小

- 气圈张力降低,生产速度更高

操作与清洁更便捷

人体工程学

操作与清洁更便捷

中央调节,减少机器操作时间

快速、简单、精确的马达驱动系统,优化操作高度.

经过优化的所有气圈导纱钩高度一致.

卷装输送带可快速搬运成品卷装纱

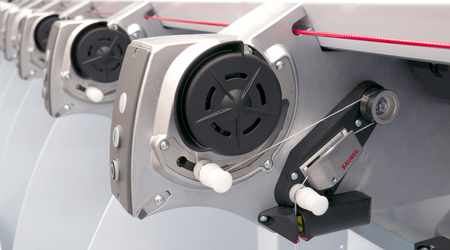

Volco-/Creeljet气动穿纱系统实现快速方便穿纱

电脑控制的伺服 - 机械式齿轮箱

为什么要在卓郎二合一倍捻机上加捻地毯纱?

原因主要包括以下二点:

- 我们的地毯纱倍捻机可以通过其升级改造工序——上行式加捻,在成本效益最大化的情况下,实现股线稳定、高效的生产,尤其可以为厚层地毯的簇绒过程提供BCF纤维单纱。

- 同时,还可通过经典的二合一倍捻工序,为机织地毯提供专用的耐磨纱线,比如,短纤纱、毛纺纱、聚丙烯酸酯纱、锦纶、丙纶和多种专用于地毯生产的混纺纱。

更多创新…

电脑控制的电子传动系统

- 快速、便捷和经济的调节装置

- 人工成本更低

- 更高的机器可操作性

- 生产效率和可靠性更高

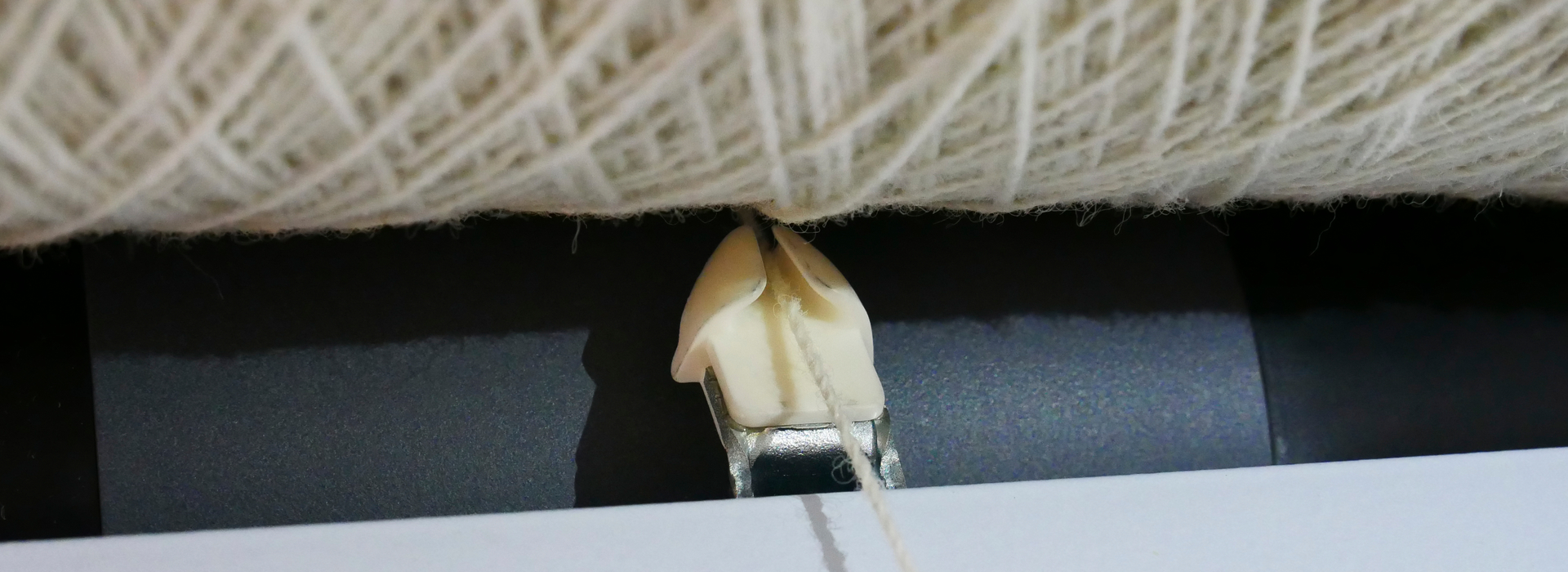

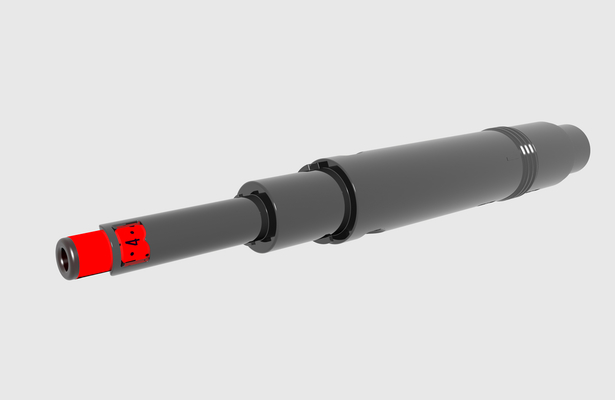

锭罐球形纱线张力器

球形纱线张力器,配备耐磨的陶瓷球,可全面调节张力。轻轻转动进纱管,即可快速调节24位张力。

图片库

相关阅读

您将找到更多上述产品的相关信息,例如:应用报告、客户成功案例和访谈。

您还可能感兴趣

Sun – 服务无限

整个生命周期内强大可靠的伙伴关系。

深具特色的智能解决方案,让客户获享更大利益。

在设备整个生命周期均实现卓越性能和可持续性。

卓郎为您铸就强大竞争实力。

咨询

安装

培训

原装备件

保养和维修

升级和改造

Secos – Saurer 客户门户

联系我们

如果您对我们的产品有任何疑问或需要其他帮助,请与我们当地代表联系。作为您的合作伙伴,能为您提供专业而快速的支持服务是我们的荣幸。