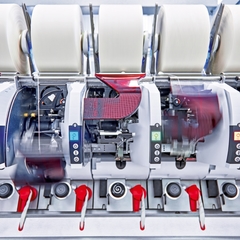

Additional DCUs for your Autocoro

for increased doffing flexibility & productivity

Reacting flexible on market demands is the key to success.

If the doffing capacity is no longer sufficient, e.g. when changing from finer to coarser yarns for recycling, upgrade your Autocoro with additional DCUs.

For more machine efficiency, more productivity, more profit.

Reacting flexible on market demands is the key to success.

If the doffing capacity is no longer sufficient, e.g. when changing from finer to coarser yarns for recycling, upgrade your Autocoro with additional DCUs.

For more machine efficiency, more productivity, more profit.

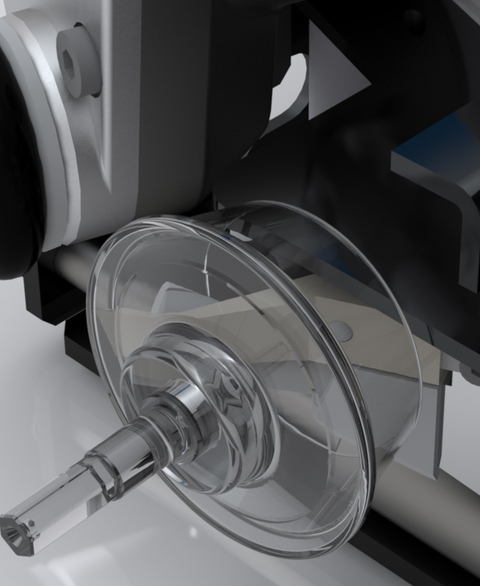

Rotor cleaning device for your DCU

For optimised mechanical and pneumatic cleaning

- New: Feature from Autocoro 10 now available for Autocoro 9 and 8

- Integrated new patented linear rotor cleaning device in the DCU for pneumatic and mechanical cleaning

- With new interval function: During the cleaning cycle the rotor scraper dips several times into the rotor groove

- The layer of dirt will be broken and removed very easily

- Especially recommended when spinning raw materials creating a tenacious layer of dirt inside the rotor, e.g. honeydew

Our offer

Upgrade your Autocoro pairwise with two or more additional, completely assembled DCUs:

- Up to 8 DCUs for Autocoro 10

- Up to 6 DCUs for Autocoro 9

- Up to 4 DCUs for Autocoro 8

Your benefit

More flexibility

- Gain more flexibility and avoid inefficient waiting times during doffing

- Especially recommended for processing coarser yarns or small packages or after machine extensions

Greater productivity

- Up to 3% greater machine efficiency

- Short ROI (return on investment)

- More preventative rotor cleaning actions possible

Improved handling

- Inclusive new patented linear rotor cleaning device

- With new touch display

- Easy and fast installation

Application area

For all Autocoro 10, 9, 8

| Additional DCUs: Order number for all variants | 161-400.909 |

| Upgrade Rotor cleaning device DCU | 161-400.993 |

| Please contact your Parts Manager, Service Manager, or email parts.spinning@saurer.com | |

| Please always state the machine number |

Downloads

Interested? Read our fact sheet for more information.

Additional DCUs Autocoro fact sheet EN

88.29 KB

Contact us

Should you have questions about our products or require additional guidance, kindly get in touch with your local contact person. As your partner, we pride ourselves in providing expert and swift support.